Metal Industrial Control Cabinet For Harsh Environment

- IP Rating

- Wall Mounted

- With Push Button

- Siemens HMI

- 2.0MM Stainless Steel

All of the above product attributes can be customized!!!

Description

Metal Industrial Control Cabinet For Harsh Environment

Engineered for durability and performance, our Metal Industrial Control Cabinet is the perfect choice for harsh environments. With a heavy-duty construction, IP65/IP66 rating, and corrosion-resistant finish, this cabinet provides superior protection against dust, water, and extreme weather.

Whether in manufacturing plants or outdoor installations, it ensures your control systems operate flawlessly.

Specification

| Model No. | YL250219 |

| Color | RAL7035 |

| Material Specifications | Stainless steel; Carbon steel; Aluminium; Galvanized steel |

| Number Of Doors | 2 |

| Door Type | Manual close |

| Adjustable Shelves | Customizable |

| Dimentions | Customizable |

| IP (Ingress Protection) Rating | IP65 |

| Drawing Format | DWG, STEP, IGS, SLDPRT |

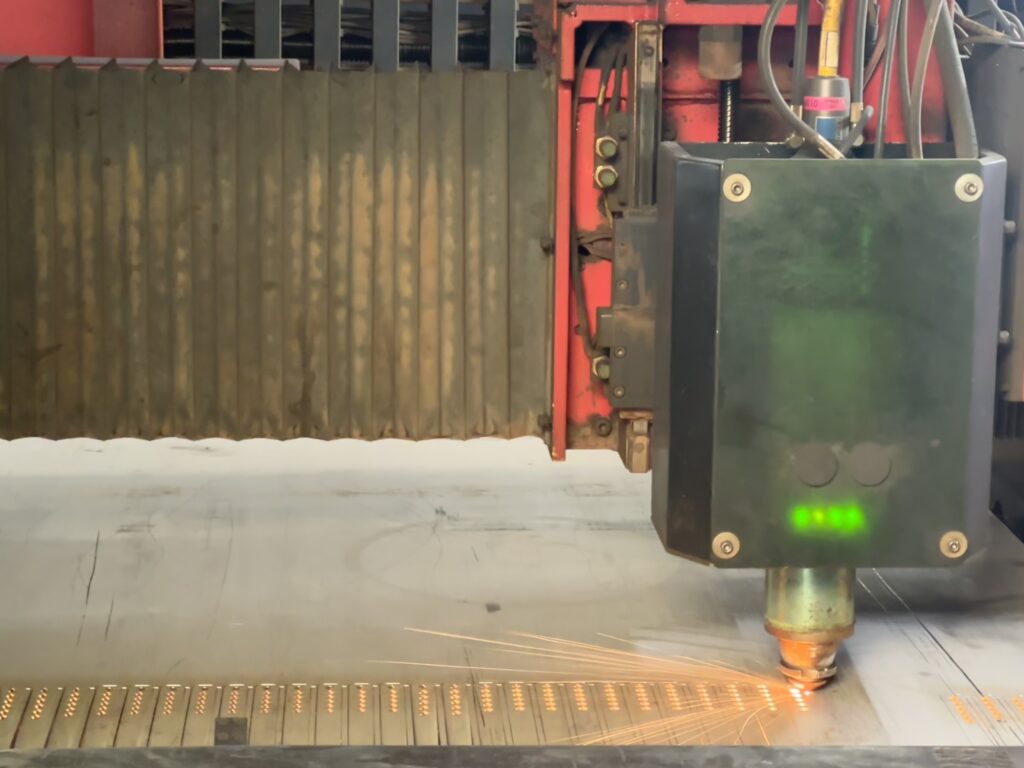

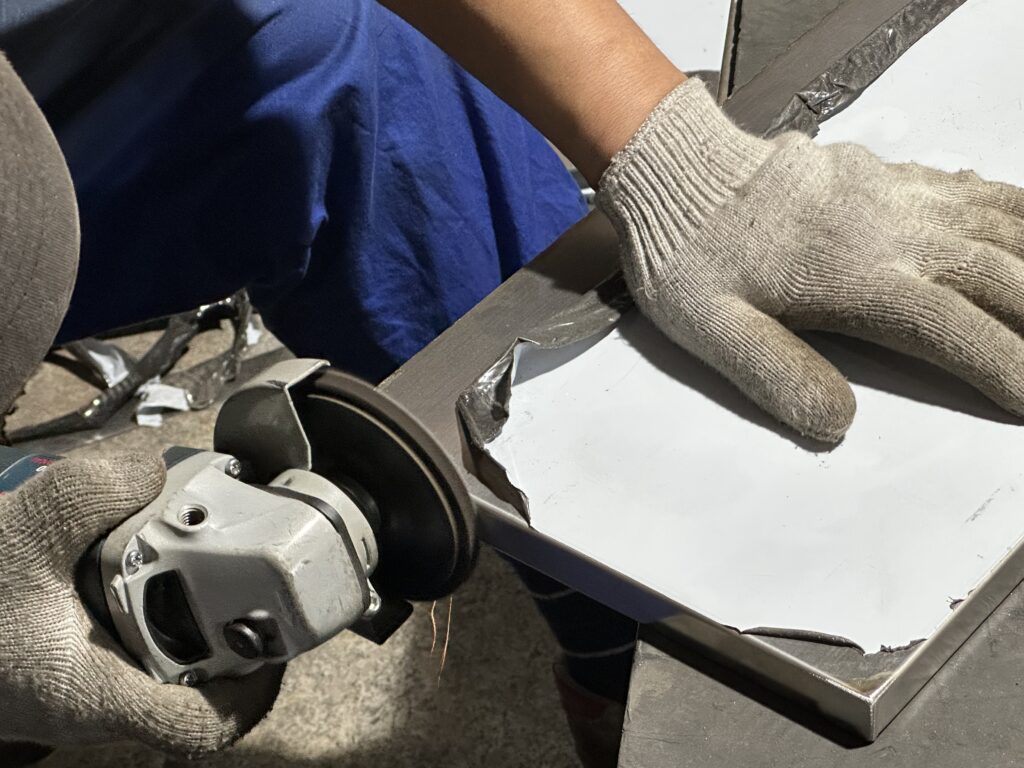

| Fabrication Process | Laser Cutting-Bending-Welding-Polishing-Assembly |

| Surface Treatment | Powder Coating / Painting / Sandblasting / Pickling / Phosphating / Electroplating / Anodizing ,etc. |

| Fully Welded Design |

Fully welded design for strength and durability |

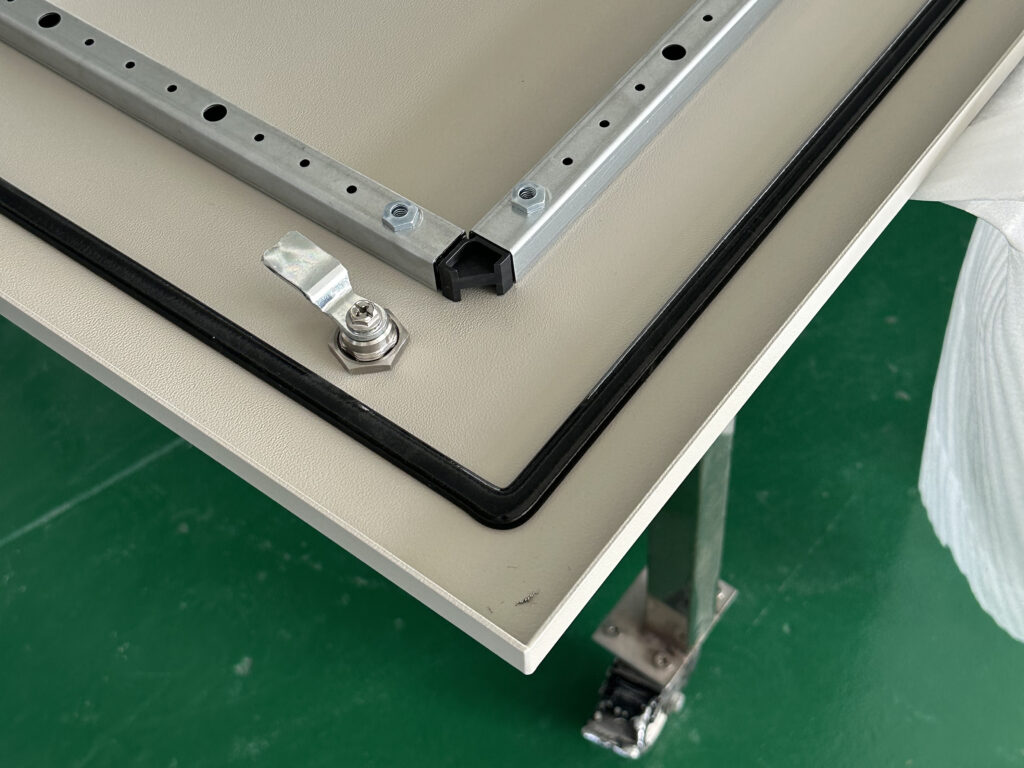

| Dustproof And Waterproof Capability | Rain cover and sealing strip have waterproof function |

Product Design and Structure

Overall Design

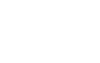

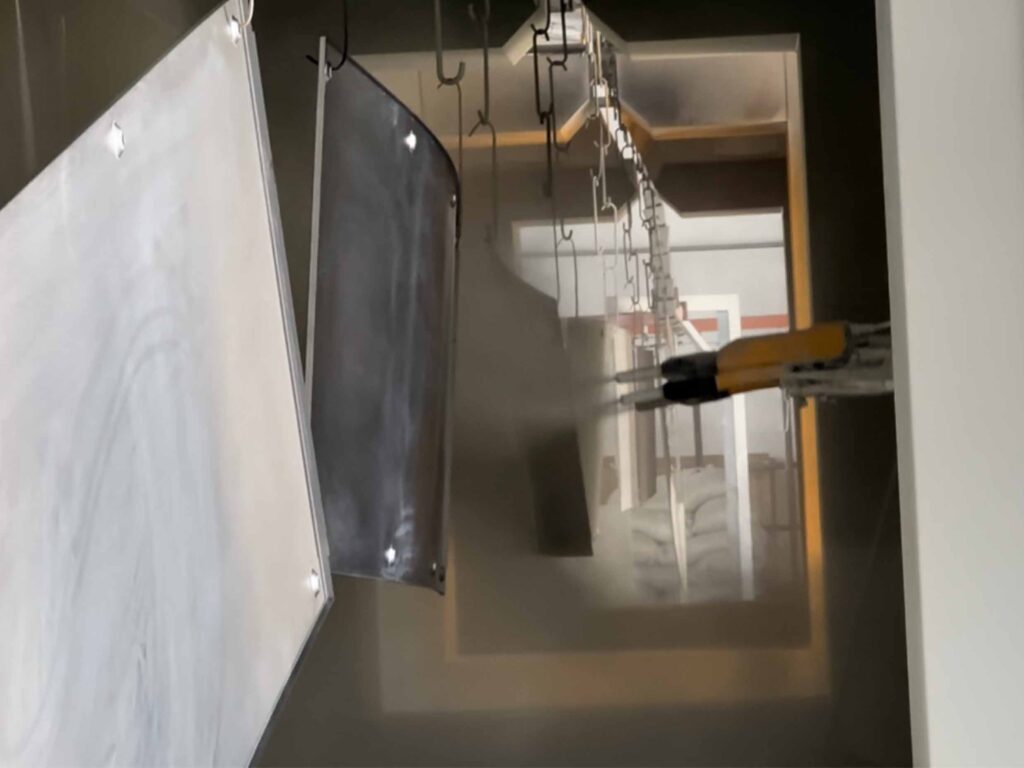

Sealing Design: We have professional sealing foam machines. These machines are used to precisely apply sealing strips around parts of the cabinet such as doors and vents, ensuring the cabinet achieves a high – level of airtightness. This effectively prevents pollutants like dust and moisture from the harsh environment from entering.

|

|

Figure No.1 Sealing Foam Machine

Reinforced Structure: For the frame part of the cabinet, we use thickened steel and add multiple reinforcing ribs. This enhances the structural strength of the cabinet, enabling it to resist relatively strong external impacts.

Internal Structure

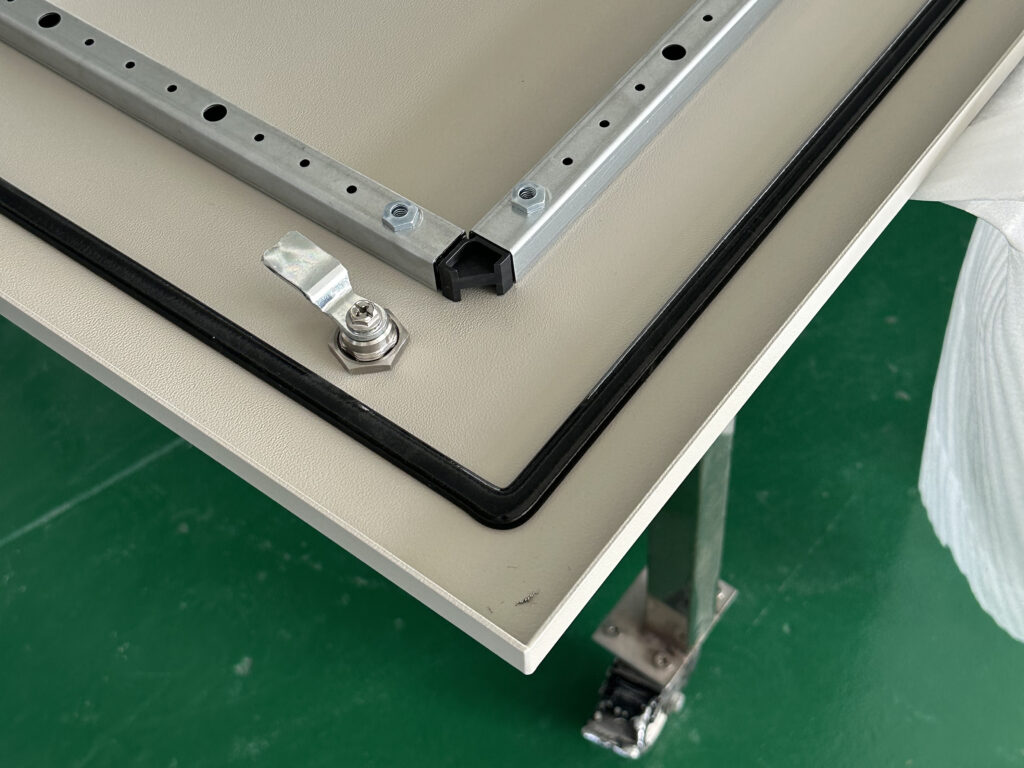

DIN Rails: We rationally set up multiple groups of standardized DIN rails on both sides inside the cabinet. The positions of these rails can be slightly adjusted according to actual needs. This enables users to easily install various PLC modules and related devices of different sizes, ensuring that the installation is firm and orderly.

Equipment Installation Plate: The installation plate features an adjustable design. By setting multiple mounting holes and adjustment screws, users can flexibly adjust the position and angle of the installation plate according to the actual size and layout of the equipment. This helps achieve the best installation effect for the equipment, improves space utilization, and meets the requirements of different equipment combinations.

|

|

Figure No.2 Industrial Control Cabinet Internal Structure

External Structure

Doors and Opening Methods

We design the cabinet doors as single – opening or double – opening forms according to the size of the cabinet. The door body connects to the cabinet body through high – strength hinges, ensuring smooth and durable door – opening and closing operations. The surface of the door has a flat and smooth design, which is easy to clean and enhances the overall aesthetics at the same time.

Locks

We equip the cabinet with high – security locks. The lock cores adopt anti – theft designs, having functions of anti – prying and anti – drilling, effectively protecting the safety of the equipment inside the cabinet.

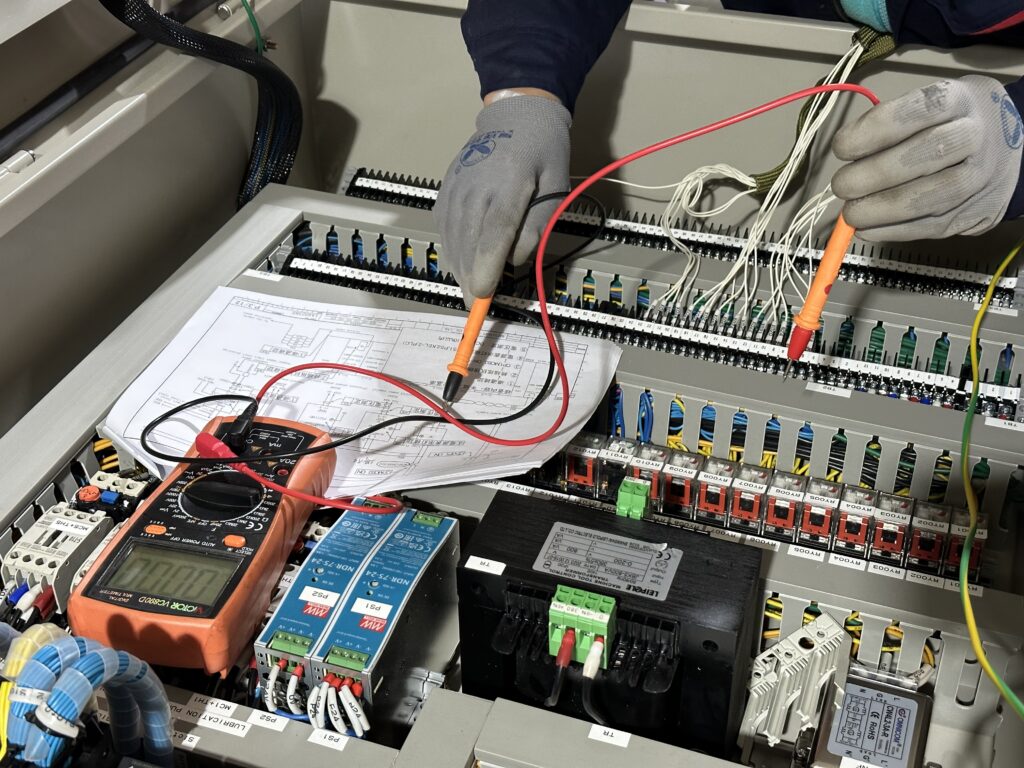

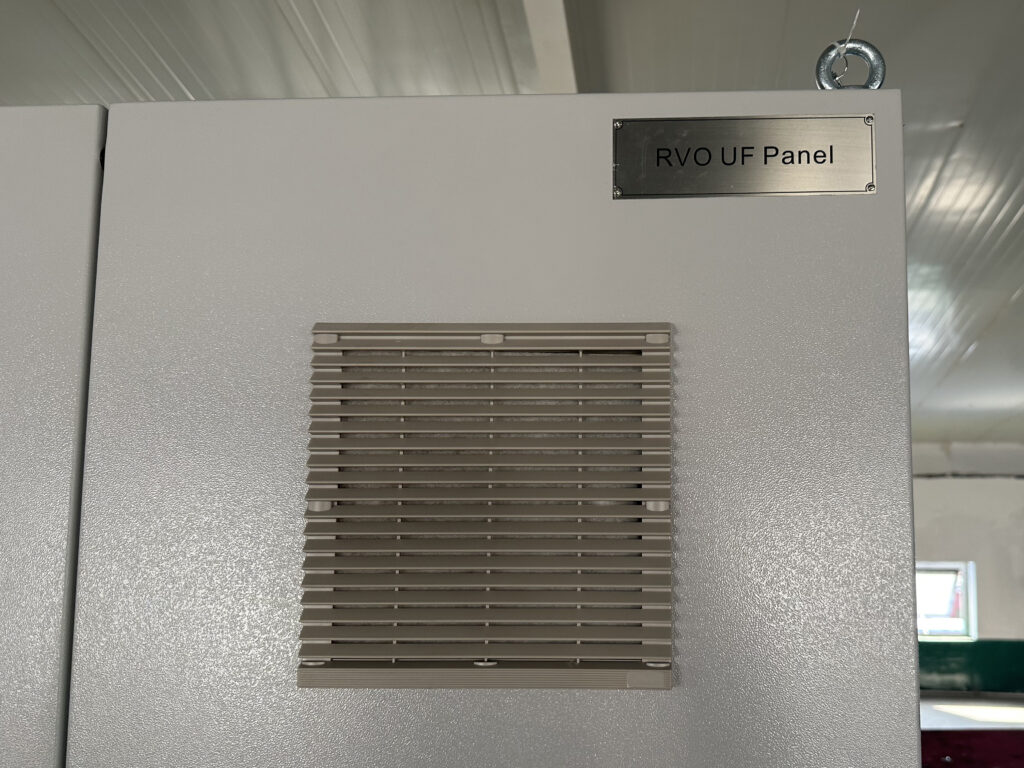

Ventilation Opening Design

The ventilation openings adopt a special louver – like structure. We set up fine dust – proof filters inside. This can not only ensure good ventilation and heat – dissipation effects, allowing the heat generated by the operation of the equipment inside the cabinet to be discharged in a timely manner, but also prevent foreign objects such as dust and insects from entering.

|

|

Figure No.3 Ventilation Opening Design

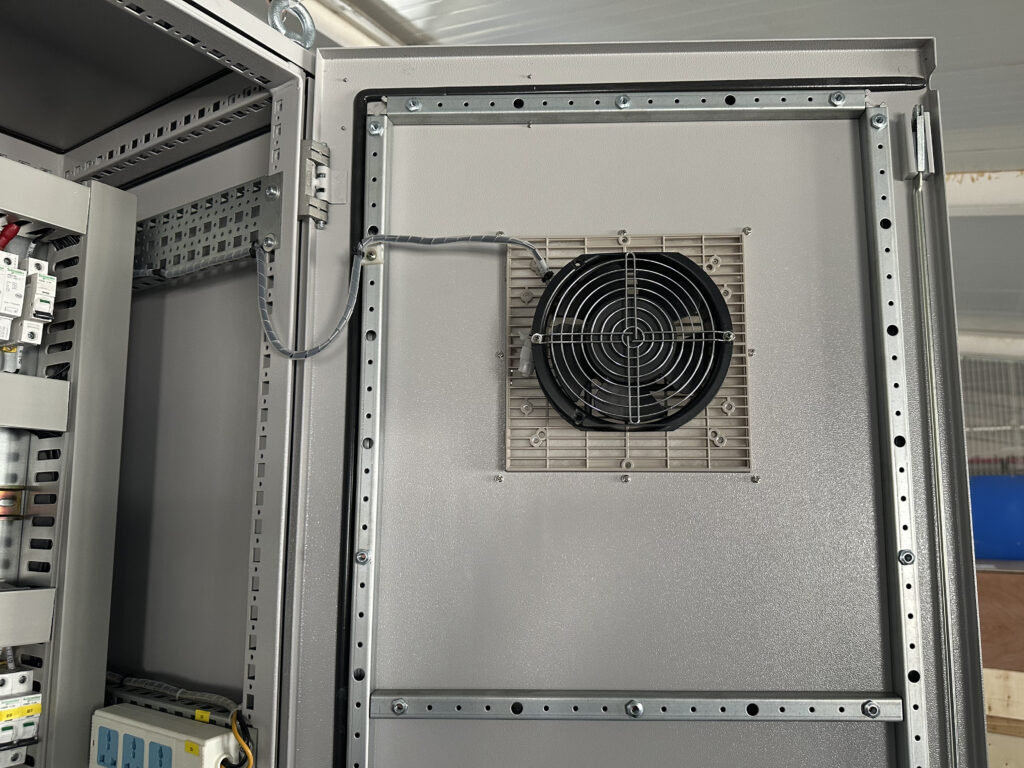

Industrial Control Cabinet Fabrication Capacity

|

|

|

|

|

|

Figure No.4 Industrial Control Cabinet Fabrication Process