Stainless Steel Enclosure Manufacturer

As a professional manufacturer of stainless steel enclosures, we can meet all your uses.

Fabrication by 304, 316 and other high-quality stainless steel

We specialize in customizing non-standard stainless steel enclosures to meet all individual needs

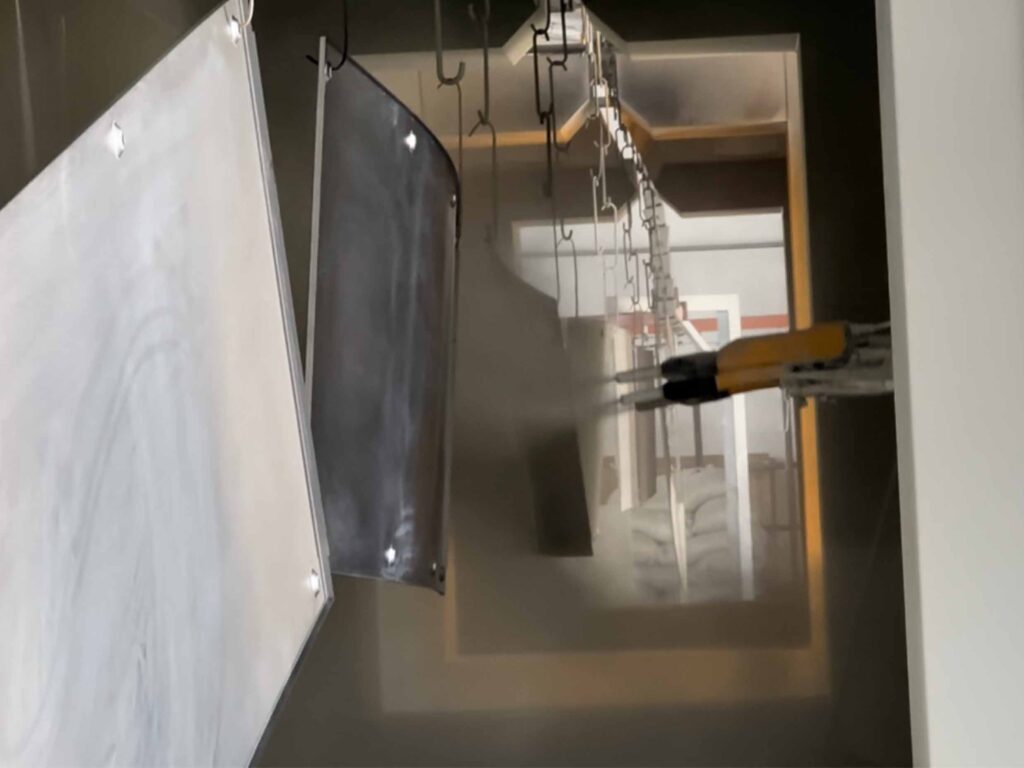

Yinlu - Fabrication Capacity

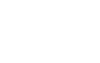

Laser Cutting For Stainless Steel Enclosure

Bending For Stainless Steel Enclosure

Welding For Stainless Steel Enclosure

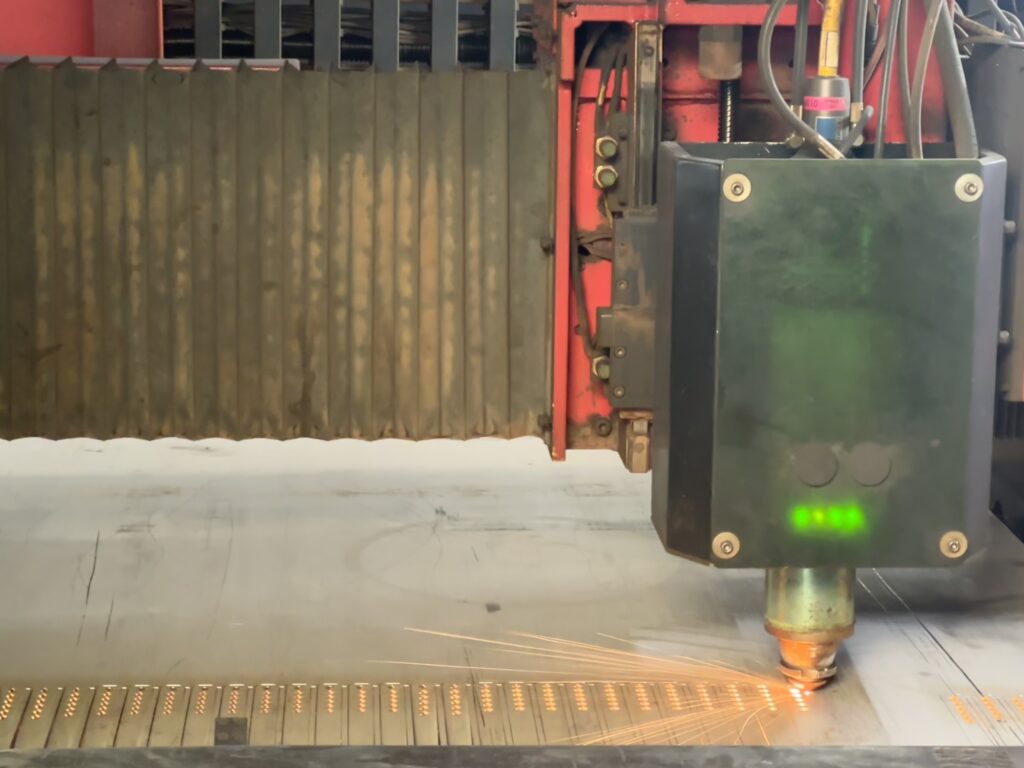

Polishing For Stainless Steel Enclosure

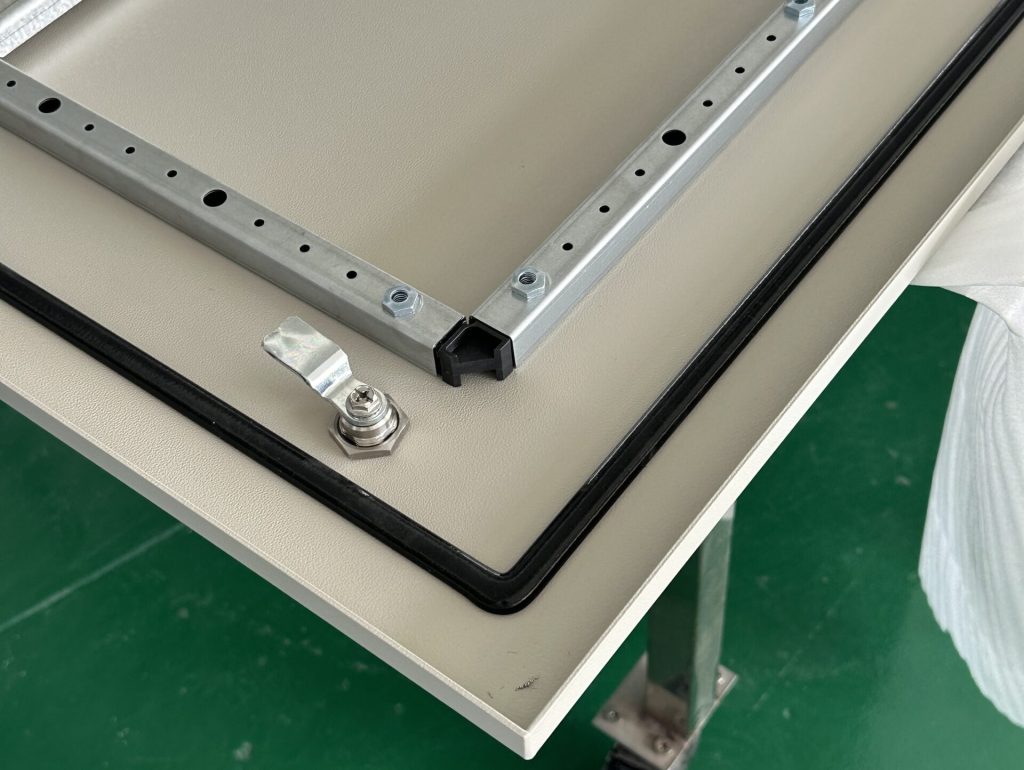

Foaming For Stainless Steel Enclosure

Powder Coating For Stainless Steel Enclosure

Table of Contents

What You May Need To Know About Stainless Steel Enclosure

- Betty

Figure No.1 Stainless Steel Enclosure Display

What is the difference between different grades of stainless steel

Stainless steel is a material with a relatively high usage rate in the process of metal enclosure processing. We have also introduced it in other articles. If you want to learn more specific details about stainless steel, you can find them in the following two articles.

Application of stainless steel in sheet metal fabrication

Sheet Metal Fabrication Material Selection Guide

The difference between stainless steel enclosure, carbon steel enclosure, galvanized steel enclosure

Ingredient

Carbon steel mainly consists of iron and carbon. Stainless steel contains additional elements such as chromium, nickel, and molybdenum on the basis of carbon steel. Galvanized steel has a zinc layer added to the surface of carbon steel through the galvanizing process.

Corrosion resistance

Carbon steel (steel) is prone to rusting and has poor corrosion resistance. The metal enclosures made of it are inferior to those made of stainless steel in this regard. Although galvanized steel has a certain degree of corrosion resistance due to the zinc layer, it is vulnerable to saline water erosion, and its overall corrosion resistance is also not as good as that of stainless steel.

Appearance

The appearance of steel (carbon steel) is usually rather dull. After rusting, it will show reddish-brown rust that affects its aesthetics. The surface of stainless steel is mostly silver-gray or bright white and maintains a good appearance for a long time. Galvanized steel has a silver-gray appearance, but the aging or damage of the zinc layer will affect its appearance.

Mechanical property

Steel (carbon steel) has relatively high strength, but its toughness may be inferior compared to that of stainless steel. However, it is magnetic and more malleable. Stainless steel has a good balance between strength and toughness and has excellent processing performance. The mechanical properties of galvanized steel are similar to those of carbon steel, and attention should be paid to protecting the zinc layer during processing.

Degree of processing difficulty

Steel (carbon steel) is relatively easy to process. However, problems like cracks may occur during cold working. When welding, appropriate techniques should be chosen to prevent defects. Stainless steel has good processing performance, but for some operations like welding, the heat input needs to be controlled. Galvanized steel is processed in a similar way to carbon steel, and the key point is to avoid damaging the zinc layer.

Cost

Galvanized steel is more expensive than stainless steel, while carbon steel has a relatively low price. However, considering factors such as the cost of protective treatment for carbon steel and its relatively short service life, the comprehensive cost needs to be weighed.

Complete process for manufacturing stainless steel enclosure

After fully discussing all the details and determining the relevant precautions, we will provide the product prototype within one week, and then proceed to the production process:

Laser Cutting: Use professional laser cutting equipment to cut out the various parts on the stainless steel sheets.

Bending : Employ a CNC bending machine to bend the cut parts according to the drawings.

Welding: Depending on the different materials, use different welding techniques to weld the various parts together and complete the main frame.

Surface Polishing: To give the product a good appearance, polish the stainless steel enclosure to make its surface smooth and thus improve the appearance quality.

Foaming: Ensure the waterproof function of the enclosure.

Powder Coating: We usually adopt the powder coating process to achieve the appearance effect expected by customers, which can realize various color effects.

Figure No.2 High quality sealing

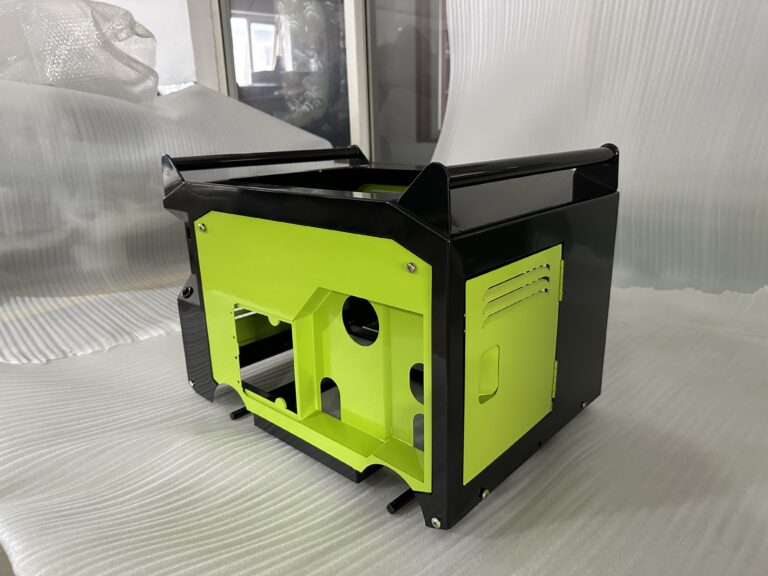

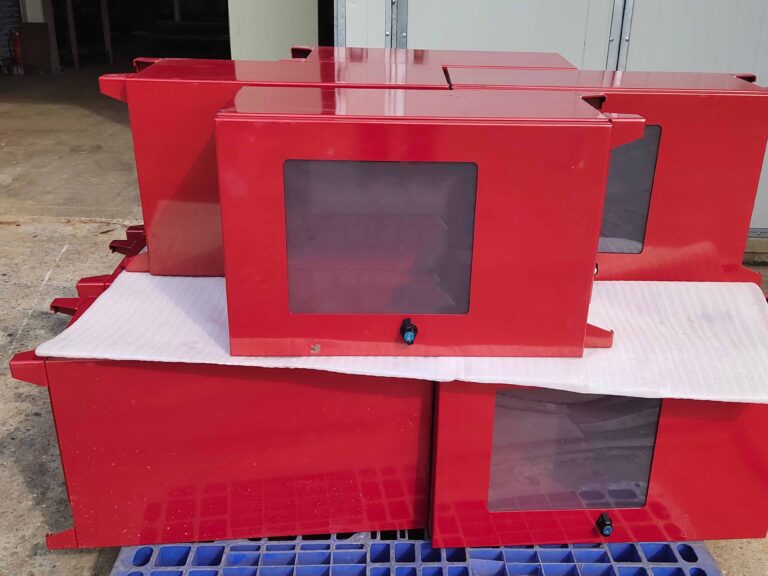

Figure No.3 Multi-color effect

What are the differences in electrical conductivity between different stainless steel materials?

In the selection of stainless steel materials for enclosures, 304, 316 and 201 are usually used more often.

If you want to know more about the properties of each type of stainless steel material in detail, you can read our articles for more information.

Application of stainless steel in sheet metal fabrication

201 Stainless Steel:

It has certain limitations in electrical conductivity. Among the stainless steel family, it is one with relatively low resistivity. So it’s not suitable for products with high requirements for electrical conductivity.

304 Stainless Steel:

Its main components include elements like iron, chromium and nickel. Since these elements have good electrical conductivity, 304 stainless steel has good electrical conductivity.

304 Stainless Steel:

Compared with 304 stainless steel, 316 stainless steel has an additional chemical element, molybdenum. As a result, 316 has better corrosion resistance, but its electrical conductivity is also reduced to some extent.

Sort them according to electrical conductivity.

304 Stainless steel > 316 Stainless Steel > 201 Stainless Steel

What is the specific impact of the hardness of the stainless steel enclosure material on its durability?

Deformation Resistance:

Although the hardness of stainless steel is not the highest among the materials in the sheet metal fabrication industry, it is at an upper-middle level.

After appropriate heat treatment, its hardness can be effectively increased, enabling it to better resist deformation caused by external forces and prevent the electrical components inside the stainless steel electrical enclosure from being damaged due to the deformation of the enclosure.

Wear Resistance:

Hardness is closely related to wear resistance. The usage environment of the stainless steel enclosure may be outdoors or in places with harsher conditions. At this time, in order to increase the hardness of stainless steel, the hardening processing technique can usually be adopted to further enhance the hardness of the stainless steel enclosure and thus improve its wear resistance.

How to reduce the manufacturing cost of stainless steel casing while ensuring quality?

Material cost control

We choose appropriate stainless steel models after considering various aspects such as the specific usage environment and functions of the stainless steel enclosure. We have reliable suppliers and the long-term cooperative relationships established with them can ensure that while reducing the cost of raw materials, high quality is guaranteed.

Process optimization

Before carrying out the key processes like cutting, bending and welding, we will do sufficient preparatory work. For example, before cutting, we will make reasonable layout for the steel plates. Before bending, we will calculate the precise bending angles and sizes to ensure that there will be as little waste as possible during the production process.

Mold making

For the mass production of stainless steel enclosures, designing and using dedicated molds can significantly reduce costs. Reasonably designing the structure and size of the molds enables the enclosures to achieve relatively high precision and quality requirements in one forming process, thus reducing subsequent processing procedures and labor costs.

What are the effects of different welding methods on the structural strength of stainless steel enclosure?

TIG Welding

Compared with other welding methods, TIG welding has a very small heat-affected zone, which can ensure better mechanical properties of the materials. Moreover, the weld quality is high, which is very beneficial to the structural strength of the stainless steel enclosure. In the welding of stainless steel electrical control cabinet enclosures with extremely high requirements, it can ensure that the structure will not be affected.

MIG Welding

This welding technique is characterized by a relatively fast welding speed and is very suitable for welding thicker stainless steel materials. It is quite advantageous for the manufacturing of some large stainless steel enclosures. However, it has a relatively large heat-affected zone and may cause slight deformation to some extent.

Laser Welding

Laser welding is a highly precise welding method with narrow welds and an extremely small heat-affected zone. Thus, it ensures good shape and high-precision dimensions of the stainless steel enclosure. It has high strength and good toughness.