Table of Contents

A Comprehensive Guide to PLC Cabinets : Types,Application,Selection

A PLC cabinet is the main part of automation systems. It holds controllers and important parts, keeping them safe from harm.

These cabinets protect electronics from dust, water, and heat changes. Picking the right PLC cabinet helps systems work well and avoid delays.

Knowing its types, uses, and how to choose one helps you decide wisely and improve system performance.

- Betty

Key Takeaways

- Pick the right PLC cabinet for your needs. Wall-mounted ones save space. Freestanding ones work better for bigger setups.

- Check for high IP or NEMA ratings for outdoor cabinets. These ratings protect against dust, water, and bad weather.

- Keep up with maintenance. Check and clean your PLC cabinet every three months. This stops dust and keeps parts working well.

- Manage heat properly. Use cooling systems to stop overheating. Overheating can harm parts and make them wear out faster.

- Make your PLC cabinet fit your needs. Change the size, features, and materials to improve how it works and lasts.

Types of PLC Cabinets

Wall-Mounted PLC Cabinets

Wall-mounted PLC cabinets are great for small spaces. These cabinets hang on walls, saving floor space in tight areas. They keep equipment safe and reduce noise in the workspace. Lockable doors stop people from tampering with the equipment. The closed design also makes the area quieter by blocking noise.

| Feature | Description |

| Enhanced | Lockable doors keep equipment safe from tampering. |

| Noise Reduction | Closed design lowers noise, making the area quieter. |

| Space-Saving Design | Wall mounting saves floor space in small rooms. |

| Physical Protection | Protects equipment from dust and accidental hits. |

Freestanding PLC Cabinets

Freestanding PLC cabinets are strong and flexible. They are perfect for big industrial jobs. These cabinets stand on the floor and hold many parts. Their design can be changed or expanded as needed.

One big advantage is how easy they are to access. There’s enough space inside for neat wiring and easy repairs. These cabinets are used in factories, energy plants, and other places with complex systems.

Outdoor PLC Cabinets

Outdoor PLC cabinets are built to handle tough weather. They are made from strong materials to last a long time.

Key features of outdoor PLC cabinets include:

- High protection rating with excellent resistance to water, dust, cold, and extreme heat.

- Made of corrosion-resistant materials, enabling long-term use.

- A multi-layer protection system safeguards internal electrical safety.

- Adopts a modular design for easy expansion and post-installation maintenance.

- Incorporates anti-theft security design to prevent tampering or unauthorized access.

Explosion-Proof PLC Cabinets

Explosion-proof PLC cabinets are crucial for dangerous workplaces. They stop sparks or heat inside from causing fires with flammable gases, vapors, or dust nearby.

To stay safe, explosion-proof PLC cabinets follow strict rules:

NFPA 79: This rule makes sure electrical parts are safe, labeled, and protected for industrial machines.

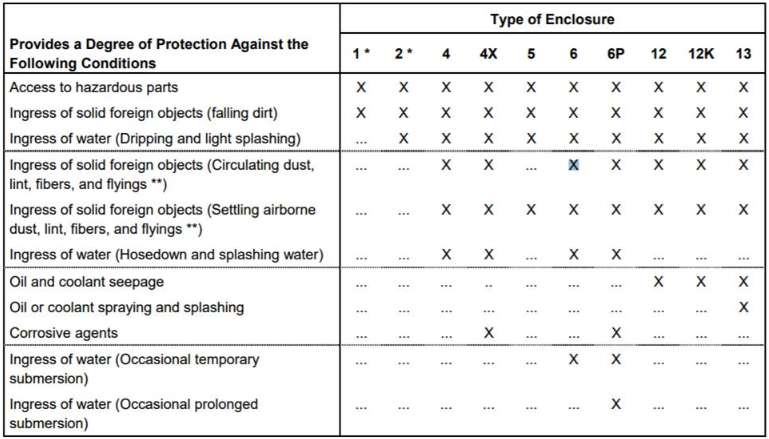

NEMA Ratings: These ratings show how well the cabinet protects against dust and water, making it strong for tough places.

Following these rules lowers accident risks and helps the cabinet survive harsh conditions. These cabinets are also built strong with tight seals and tough materials for extra safety.

Tips: Always check if an explosion-proof PLC cabinet meets NFPA and NEMA rules for the best safety and performance.

Stainless Steel PLC Cabinets

Stainless steel PLC cabinets are perfect for places with rust problems. They are made to handle tough conditions, making them great for food factories, ships, and chemical plants. Their strength and rust resistance make them last long, even in hard environments.

Main features of stainless steel PLC cabinets:

- Robust structure compliant with IP65/IP66 ratings, offering dust and water resistance.

- Corrosion resistance and high strength.

- Low maintenance cost with long-term usability.

- Suitable for both indoor and outdoor applications.

These cabinets keep control systems safe in wet or rusty areas. Their clean look also makes them popular for clean industries like food and medicine production.

Notes: Stainless steel PLC cabinets are a smart choice for strength and good looks.

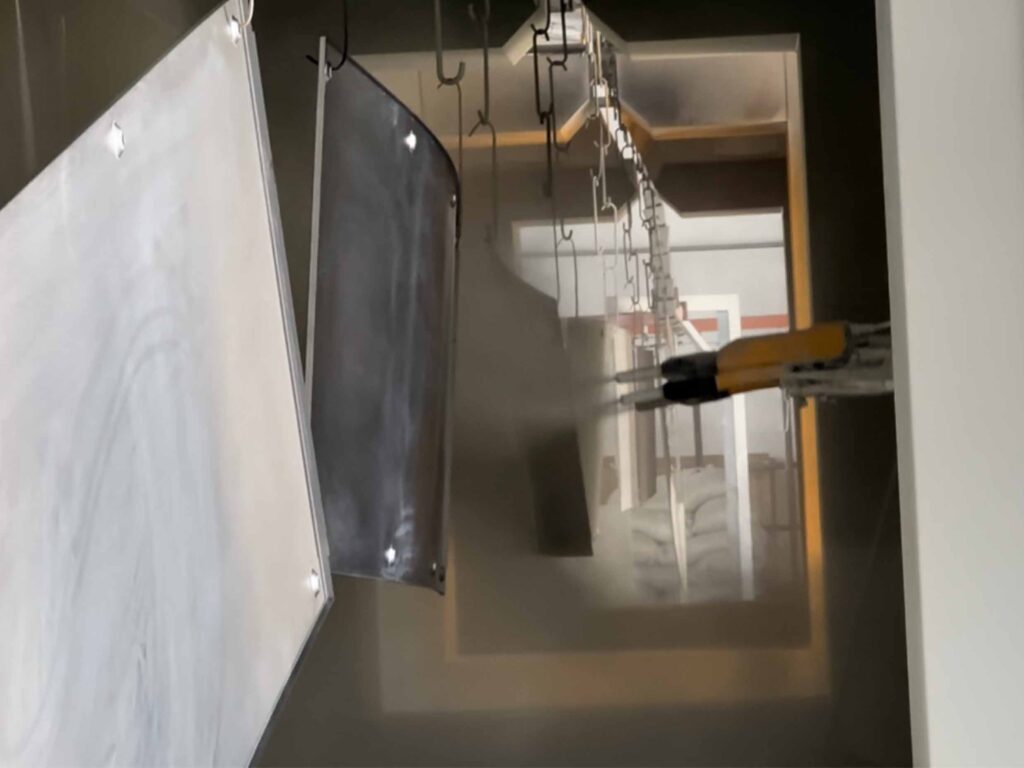

Powder-Coated Steel PLC Cabinets

The powder-coated steel cabinet is a common type of industrial cabinet. Based on the ordinary steel cabinet, its performance and durability are enhanced through the powder coating process.

- Good protection performance

- Diverse appearance options

- Environmentally friendly, insulated, and cost-effective

Powder-coated steel Electrical cabinets can last 15–20 years, depending on the coating type. This makes them a good pick for cutting maintenance costs. Plus, their colorful finish looks nice and protects against the weather.

Figure No.1 Yinlu‘s Auto Powder Coating Production Line

A Step-by-Step Guide to Selecting the Right PLC Cabinet

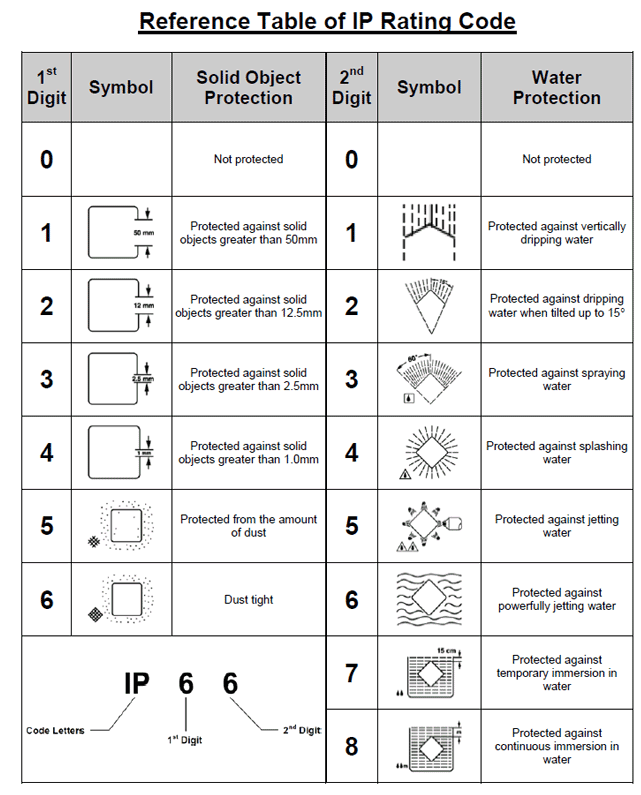

Environmental Protection (IP Ratings, Dust, and Water Resistance)

Choosing a PLC cabinet means thinking about its environment. Check for temperature, humidity, dust, and harmful air. Cabinets with the right IP or NEMA ratings keep equipment safe and lasting longer.

IP ratings show how well a cabinet blocks dust and water. For instance, an IP65 cabinet stops all dust and low-pressure water sprays. NEMA ratings also explain how cabinets handle tough conditions.

Figure No.2 IP Rating Standard

Figure No.3 NEMA Standard

Tips: Match the cabinet’s rating to your environment. For outdoor or risky areas, pick higher-rated cabinets to avoid problems.

By checking these details, your PLC cabinet will work well, even in tough spots.

>>> Please Continue Reading

Thermal Management (Cooling Systems and Ventilation)

Keeping your PLC cabinet cool is very important. Too much heat can harm parts and shorten their life. Lowering the temperature by 18 °F (10 °C) can double the life of electronics.

Things to think about for cooling:

- Know the temperature range your PLC and parts need.

- Use cooling units for very hot places.

- Make sure vents stop heat from building up.

Notes: Good cooling makes your equipment last longer and work better. It also lowers repair costs over time.

Functional Requirements (Size, Layout, and Cable Management)

The size and setup of your PLC cabinet affect how it works. Most cabinets are 1800 mm tall, 600–1200 mm wide, and 600–800 mm deep.

Recommendations for related articles:PLC Control Panel Layout Design Optimization

| Aspect | Specification/Consideration |

| Component Placement | Place PLCs and modules in the center for shorter wires. |

| Wiring Routes | Use wire ducts and separate high and low voltage wires. |

| Maintenance Accessibility | Add lights, locks, and labels for safety and easy access. |

Organized wiring is also key. Neat wires lower mistakes during setup and repairs. They also help air move better, keeping the cabinet cooler.

Tips: Plan your cabinet for future changes. This way, you can upgrade without starting over.

By focusing on these needs, you’ll have a PLC cabinet that works well and is easy to fix or improve.

Customization Choices (Size, Features, and Materials)

Making a PLC cabinet fit your needs is important. You can change its size, add special features, or pick strong materials. These changes help the cabinet work better and last longer. Customizing also makes sure it fits well with your current setup.

Dimension specifications: The height, width, and depth can be customized according to the quantity and height of the installed equipment.

Material selection: There are various options of materials, such as cold-rolled steel plate, stainless steel, galvanized steel, aluminum alloy, etc.

Protection performance: Different IP protection ratings can be customized.

Heat dissipation and temperature control: Depending on the heat generation of the equipment inside the cabinet and the ambient temperature, different numbers and specifications of cooling fans, heat exchangers, air conditioners, etc. can be installed.

Internal layout and electrical configuration: Different forms of mounting plates can be customized to meet the installation requirements of different equipment. Also, the positions and quantities of cable inlets and outlets can be customized, which not only facilitates subsequent management but also keeps the interior of the cabinet clean and orderly.

Additional functions: Additional functions such as lighting systems, monitoring systems, electromagnetic shielding, etc. can be added according to the actual usage requirements.

Through the above rich customization options, the PLC Enclosure can better adapt to various complex industrial environments and application requirements, providing a safe and reliable operating environment for PLC and related equipment.

Following Industry Rules (EMI Protection, Certifications)

Following industry rules keeps your PLC cabinet safe and reliable. Rules about electromagnetic interference (EMI) and certifications make sure your cabinet works well and meets safety standards.

EMI Protection

Electromagnetic interference can mess up electronics. To stop this, your PLC cabinet needs good EMI protection. Rules like IEC 61000-6-2 and IEC 61000-6-4 make sure the cabinet handles interference and doesn’t cause problems. This keeps your equipment and the area around it safe.

FAQ

- What does a PLC cabinet do?

A PLC cabinet keeps automation parts safe from dust, water, and heat. It helps the system work well and stay safe. It also organizes equipment for easy fixes and upgrades. - How can you pick the best PLC cabinet for outdoor use?

Choose a cabinet with strong IP or NEMA ratings like IP65 or NEMA 4X. These ratings protect against water, dust, and rust. Use materials like stainless steel or powder-coated steel for outdoor durability. - Why is keeping PLC cabinets cool important?

Too much heat can harm electronic parts and make them wear out faster. Cooling systems like fans or air conditioners stop overheating. This keeps the system working well and avoids breakdowns. - Can PLC cabinets be made to fit special needs?

Yes, you can change PLC cabinets to match your needs. You can adjust their size, layout, or materials. Add features like extra cable holes, modular panels, or better cooling for specific tasks. - How often should you check a PLC cabinet?

Look at and clean your PLC cabinet every three months. Regular checks stop dust buildup, find loose wires, and keep parts working. This care makes the cabinet last longer and avoids sudden problems.