Steel Enclosure Manufacturer

- Sample design

- Personalized customized service

- The most cost effective solutions

Table of Contents

FAQ about steel enclosure

- Betty

How to choose the right steel enclosure

You need to comprehensively consider the following aspects when choosing a steel enclosure suitable for your project.

Consider what protection level is required according to the usage environment of the steel enclosure. The higher the number of the protection level is, the stronger the protection performance it represents. IP Rating

For some precision electronic instruments that require the enclosure to have a good electromagnetic shielding function, it’s easier to achieve the electromagnetic shielding effect by choosing steel materials with high electrical conductivity.

If it is to be used in coastal areas or environments with corrosive gases, you should take into account the corrosion resistance of the steel enclosure. In order to enhance its corrosion resistance, special surface treatment processes (such as galvanizing, nickel plating, painting) are usually carried out.

You must choose steel materials with an appropriate thickness and adopt a reasonable structural design to effectively improve the strength of the steel enclosure and avoid the impact on internal components caused by external impacts.

Ensure that the internal space of the steel enclosure is reasonably designed and there is enough space for wiring, heat dissipation, and the installation and maintenance of equipment.

Ensure that the steel enclosure can adapt to temperature changes.

Consider the installation method.

For application scenarios with high requirements for appearance, make sure that the appearance design of the steel enclosure coordinates with the surrounding environment.

If you have a steel enclosure needs or questions can contact us.

What are the standards for the size specifications of the steel enclosure

International Electrotechnical Commission (IEC) Standards

It’s the international standard regarding the ingress protection (IP code) of electrical equipment enclosures. Although this standard mainly focuses on the protection level, it also involves some basic requirements for the size of enclosures.

National Electrical Manufacturers Association (NEMA) Standards

It’s a standard for electrical equipment enclosures, which defines multiple types of enclosures, including steel enclosures. According to different application environments and protection requirements, this standard stipulates the size ranges of enclosures.

Common Enclosure Sizes

Steel Enclosures for Switchgear Cabinets:

Height: 2000mm, 2200mm, 2400mm

Width: 400mm, 600mm, 800mm, 1000mm

Depth: 600mm, 800mm, 1000mm

Steel Enclosures for Control Cabinets:

Height: 600mm, 800mm, 1000mm, 1200mm

Width: 400mm, 500mm, 600mm

Depth: 400mm, 500mm, 600mm

Steel Enclosures for Distribution Boxes:

Height: 300mm, 400mm, 500mm

Width: 200mm, 300mm, 400mm

Depth: 150mm, 200mm

How to set the ventilation structure reasonably

Firstly, you need to understand the heating power of the electrical equipment and clarify the locations and distribution of the internal heat sources.

There are two ventilation methods, namely natural ventilation and forced ventilation. After calculating the ventilation volume, you can choose different ventilation methods according to the actual requirements.

Generally speaking, the air outlet should be set at the places where hot air tends to gather, usually at the top or on the higher positions of the side of the steel enclosure.

After designing a reasonable ventilation channel, you need to check the internal structure of the steel enclosure again to avoid the occurrence of ventilation dead corners.

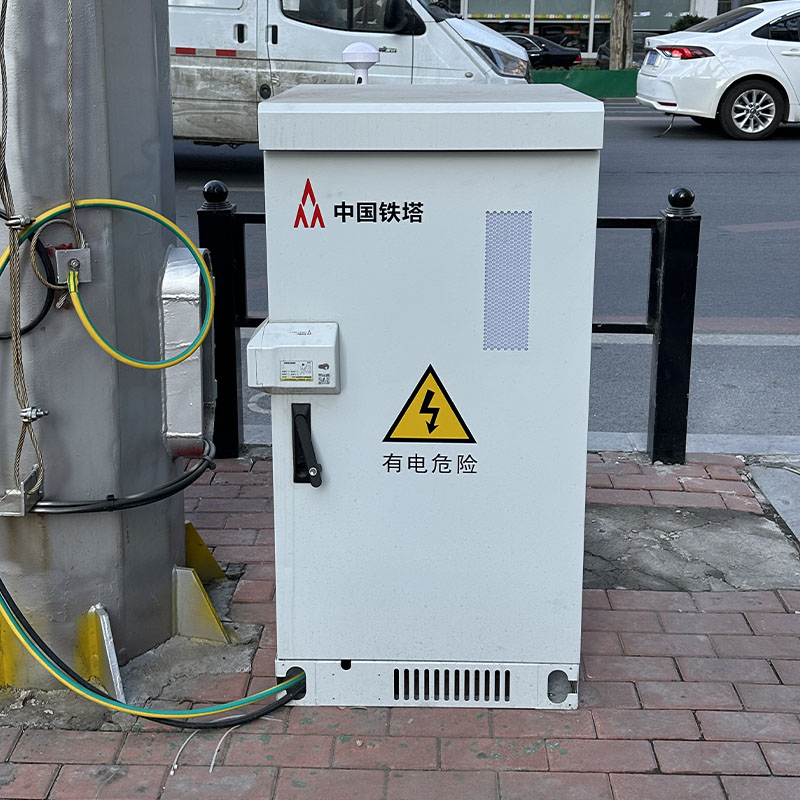

How can steel enclosure prevent small animals from invading

Steel enclosures that are used outdoors are highly prone to the invasion of small animals. Generally, these animals have the habit of gnawing. Once they enter the inside of the steel enclosure, they are very likely to gnaw on the internal wires or leave their excrement behind. For instance, in a power distribution cabinet, it’s quite possible to trigger a short-circuit fault.

We often use rubber sealing strips with good elasticity. When closing the door, the sealing strips can fit closely and effectively fill the gaps, preventing mice and other small animals from creeping in through the door cracks.

To seal the cable entry holes, we can adopt sealing putty to fill them according to the shape and size of the holes. After hardening, the putty can effectively seal the holes.

Or we can install rat guards around the bottom of the steel enclosure and set up some obstacles as well.

What are the installation ways of steel enclosure

Small steel enclosures can be installed in a wall-mounted way.

You can directly use expansion screws to fix the steel electrical enclosures on the walls. When it’s inconvenient to install them on the walls outdoors, you can also adopt the bracket-mounted way for wall installation.

Besides, you can use pole-mounted installation to directly fix them on the outdoor utility poles.

For slightly larger steel enclosures of electrical equipment, such as switchgear cabinets or power distribution cabinets in outdoor substations, the direct floor-mounted installation method will usually be adopted.

Benefits of steel enclosure

- Steel enclosures have excellent strength and rigidity, which can effectively protect the internal electrical equipment from external forces.

- The stability of steel makes steel enclosures not easy to deform during long-term use.

- Thanks to its good electrical conductivity, a steel enclosure can serve as an electromagnetic shielding cover, effectively blocking external electromagnetic interference from entering the inside and also preventing the electromagnetic signals generated by internal equipment from leaking into the external environment.

- It has good heat dissipation performance and is convenient for the design of heat dissipation structures.

- Steel enclosures can resist frequent contact and friction, are not prone to surface damage, thus maintaining the integrity and protection performance of the enclosures.

- The corrosion resistance can be improved through surface treatment methods such as galvanizing, nickel plating and painting.

- It is recyclable.

The influence of steel thickness on the properties of steel enclosure

The increase in thickness can enhance the overall strength of the steel enclosure and reduce the possibility of enclosure deformation.

However, it will have a certain impact on the electromagnetic shielding function.

It may also affect the heat dissipation speed to some extent.

Moreover, the increase in steel thickness will lead to a rise in cost and a significant increase in weight. As a result, the transportation cost and difficulty will also go up.