What personalized sheet metal customization services does Yinlu provide?

We offer full-process custom sheet metal prototype fabrication services, covering demand analysis, design and scheme confirmation, production and quality control, as well as delivery and after-sales service, offering comprehensive support to clients.

This article will explain the importance of individual needs in today’s diverse market environment and the wide application of sheet metal products in various fields.

YINLU is committed to providing customers with personalized sheet metal solutions

Design Service

We have an experienced and creative design team.

When working with our clients, we will gain an in-depth understanding of their product needs, including dimensions, functions, and appearance requirements.

We utilize our professional knowledge and experience to make constructive suggestions on the customer’s preliminary design to improve the strength and stability of the product, while reducing the use of materials and lowering costs.

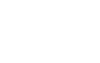

By utilizing advanced CAD, CAM and other design software, 3D models can be created quickly and accurately, allowing customers to visualize the product design.

Manufacturing Service

·Laser Cutting

Yinlu is equipped with a number of professional laser cutting machines, using high energy density laser beam to cut metal sheets, with high cutting precision, fast speed, smooth incision and other advantages. It can cut various parts with complex shapes, and is suitable for products with high precision and complex shapes.

We can choose the most suitable cutting technology according to the needs of customers and the characteristics of the parts to ensure that the cutting accuracy and edge quality meet the requirements.

·Bending

We have advanced bending equipment and experienced operators to ensure that the bending Angle is accurate. For sheet metal of different thickness and material, different bending abrades and process parameters need to be selected.

The operator will adjust the bending parameters according to the situation, and the best bending effect has been obtained.

·Welding

Welding is crucial in sheet metal customization. We usually provide argon arc welding, carbon dioxide welding and spot welding, for different materials we choose the most suitable welding methods to ensure reliable welding quality.

For example, argon arc welding is suitable for stainless steel and other metals, the weld quality is high but the speed is slow and the cost is high; Carbon dioxide shielded welding is efficient and low cost, suitable for steel structure, and the weld is rough; Fast spot welding is suitable for thin sheets, but the strength is low.

·Polishing

The importance of polishing in sheet metal processing is to improve the appearance quality and surface smoothness of the product, lay the foundation for subsequent surface treatment, can remove burrs, scratches, welding slag and other defects, and improve the overall quality.

The grinding process is required to be carried out in the order from rough to fine, with moderate strength, and the direction is consistent with the surface texture to avoid repeated grinding in the same part.

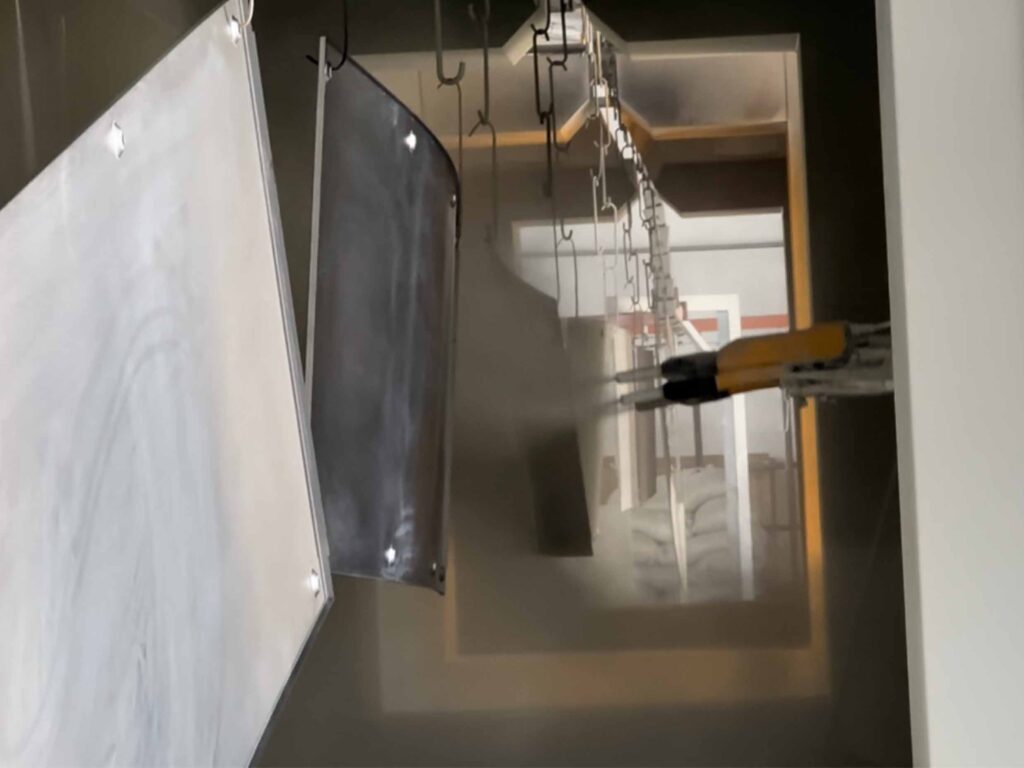

·Powder Coating

The paint is evenly sprayed on the surface of the sheet metal by the spray gun to form a protective film to improve the appearance quality and corrosion resistance of the product. Different paint types and colors can be selected to meet the individual needs of customers.

We have advanced spraying equipment and professional spraying technicians to ensure uniform spraying quality and strong adhesion. And provide a variety of surface treatment options to meet the functional and aesthetic needs of different products.

·Assemblying

Assembly is an important finishing touch for sheet metal customization. Before assembly, the parts should be inspected to ensure that there are no defects and meet the design requirements. The assembly process should be carried out in strict accordance with the assembly process to ensure the assembly accuracy.

Inspect the appearance after assembly to ensure that there are no scratches, deformation, color difference and other defects;

Overview

In short, our sheet metal customization services cover the whole process of design, processing, quality control, assembly, etc., with advanced technology and professional team to meet individual needs, to provide customers with high-quality sheet metal products and quality services.

Please visit our company website [ www.yinlu-sheetmetal.com] for more details.