AMADA LCG3015 3.5KW CO2 Laser Cutting Machine

A good laser cutting machine has an important role in sheet metal processing production with high-precision cutting, efficient processing, flexible processing capacity, material saving and environmental protection and energy saving, and is a key equipment for modern sheet metal processing enterprises to improve production efficiency, improve product quality and reduce costs.

Laser cutting machine and sheet metal processing

High-speed machining performance

·The fast feed rate of X axis and Y axis can reach 170m/min, which can efficiently complete the cutting of the plate and greatly improve the production efficiency.

·The mass of the Y-axis slide is reduced by 30% compared to traditional laser cutting machines, which makes the equipment more flexible during operation and further improves the processing speed.

High quality processing results

·Equipped with a new oscillator specially designed for the processing of thinner materials, it has a high beam focusing capability, which can improve the surface roughness of the workpiece and improve the cutting quality.

·Using AMADA’s latest HS capacitive laser cutting head, it can smoothly and quickly follow the outline of the plate, even if the plate is not completely flat, it can maintain a stable cutting, ensuring the cutting accuracy and quality.

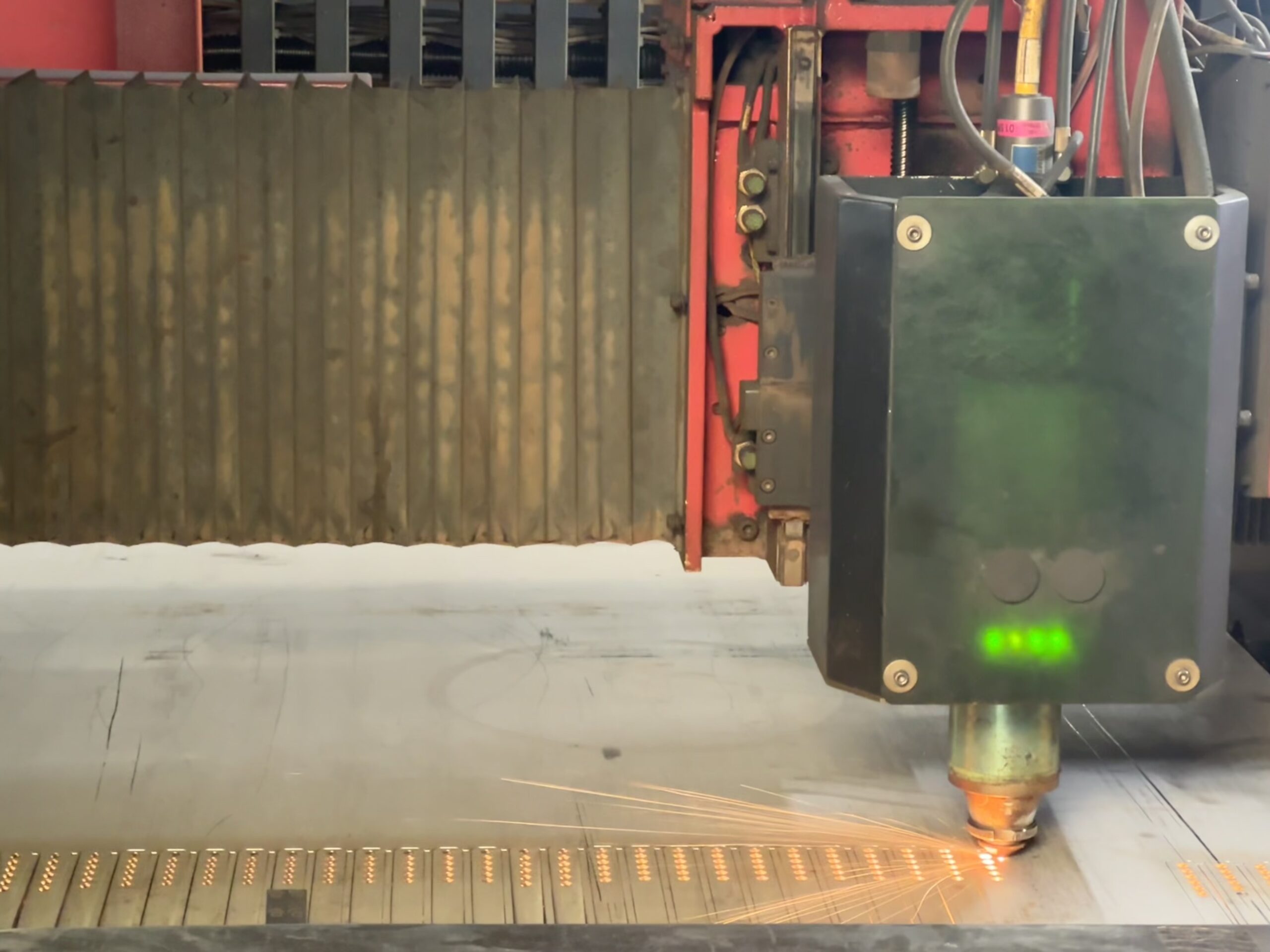

Figure No.1 AMADA LCG3015 3.5KW CO2 Laser Cutting Machine Working

Features and energy saving benefits

·With the energy-saving “Eco Cut”, an efficient oxygen-assisted cutting process, operating costs are reduced by reducing processing time and auxiliary gas consumption

·When the machine is in standby, it automatically switches to the energy-saving mode, which significantly reduces energy consumption in stages, helping to save energy and reduce the cost of use.

·The use of long-life optical components extends the cleaning and replacement intervals of optical components such as lenses, reducing maintenance costs and equipment downtime.

Convenient operation and maintenance

·The cutting head is equipped with a simple, fast-changing lens and nozzle assembly, and two cutting lenses are available as standard, a 5-inch lens for thin sheet cutting, a 7.5-inch lens for thicker sheet cutting, and a 7.5-inch lens for cutting the entire material range if required. Convenient for users to select and replace according to different processing needs.

·Before cutting the medium thick plate, oil will be sprayed on the surface of the material to prevent the accumulation of sputtering, improve the processing quality and ensure the stability of the cutting process.

Large processing range

·The maximum processing size is 3070×1550×100mm, which can meet the processing needs of most plates

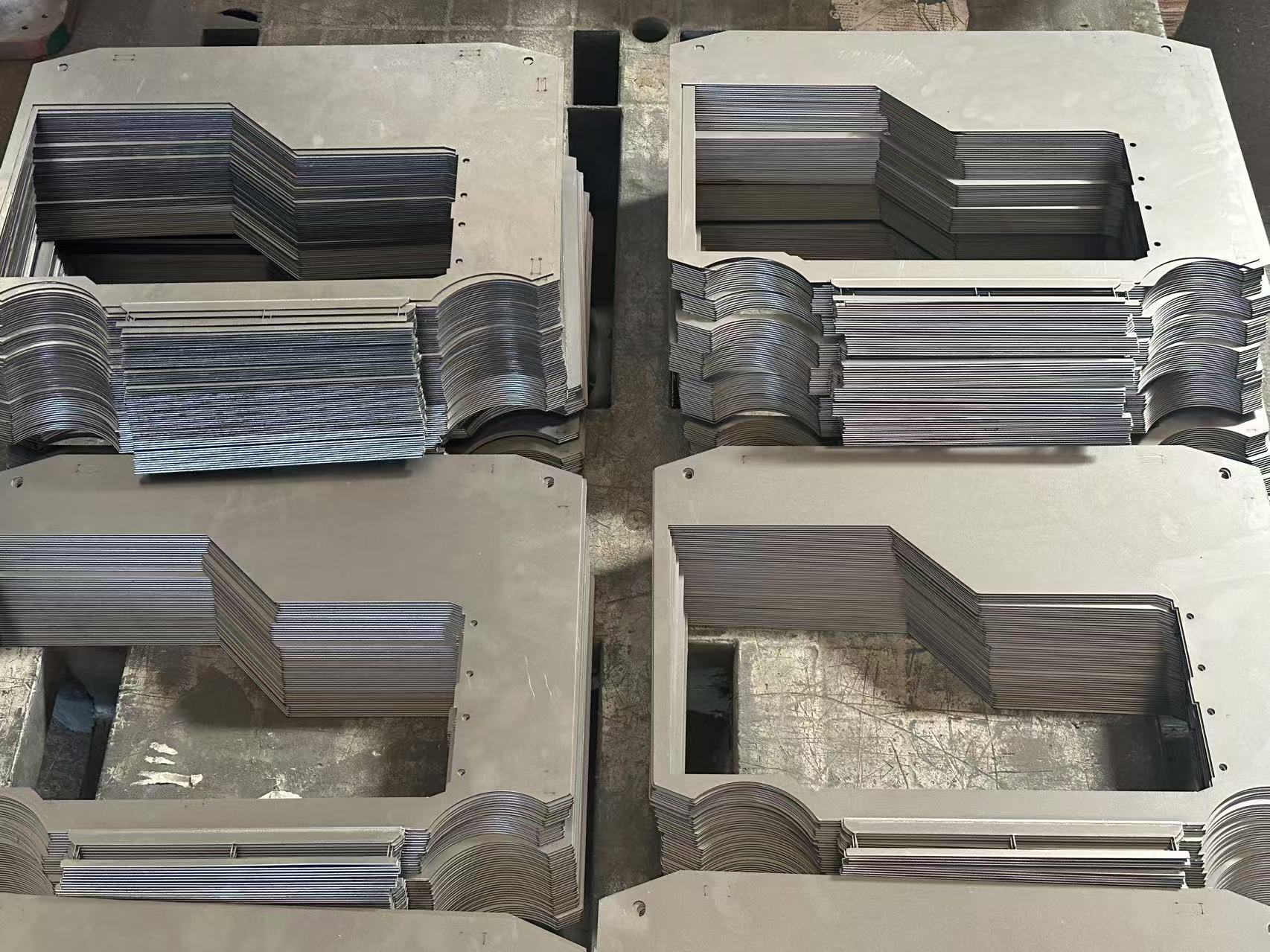

Figure No.2 Cutting effect display

Overview

AMADA, as a well-known brand of sheet metal equipment, has always had a good reputation in terms of stability and reliability of equipment. AMADA LCG3015 3.5KW CO2 Laser Laser cutting machine has excellent performance in processing speed, quality, energy saving and operation and maintenance. It is suitable for cutting all kinds of metal sheets. It is an industrial processing equipment with excellent performance.

Yinlu is also equipped with more professional sheet metal equipment, Please visit our company website[www.yinlu-sheetmetal.com] for more details.