Table of Contents

Why Stainless Steel Enclosures Are Perfect for the Industrial Field

Key Takeaways

- Stainless steel enclosures are tough and long-lasting, perfect for rough industries.

- They don’t rust or corrode, keeping equipment safe in wet places.

- These enclosures can handle heat or cold without bending or breaking.

- Stainless steel is simple to clean, cutting costs and saving time in factories.

- They can be made to fit special needs, improving how they work.

High Strength and Durability

Material's Mechanical Properties

Tensile Strength

Stainless steel is very strong and handles heavy forces well. For example, 304 stainless steel can handle forces from 210 MPa (30,000 psi) to 1,050 MPa (153,000 psi). This means stainless steel enclosure won’t bend or break easily.

Yield Strength

Yield strength shows how much stress a material can take before changing shape. Annealed 304 stainless steel has a yield strength of 200-250 MPa. Cold-worked versions can go up to 300 MPa. This helps stainless steel enclosures stay strong under pressure.

Hardness

Stainless steel is hard because of elements like chromium. This makes it resist wear and tear. Stainless steel enclosure works well in tough jobs and lasts a long time.

Structural Strength and Flexibility

Impact Resistance

Stainless steel can take hits without breaking. This is important for safety and protecting equipment in tough conditions.

Vibration Fatigue Strength

Machines often vibrate a lot in industries. Stainless steel can handle these vibrations for a long time without cracking.

Temperature and Aging Resistance

Works Well in High Heat

Stainless steel enclosures stay strong in very hot areas. They don’t break or lose shape from heat. This makes them great for factories like energy plants or manufacturing sites.

- Stainless steel handles both hot and cold temperatures easily.

- It keeps machines safe during sudden temperature changes.

Doesn’t Warp from Heat

Stainless steel enclosures don’t bend or change shape from heat. Many materials warp when hot, but stainless steel stays steady. This helps protect machines inside, even in tough conditions.

With these features, stainless steel enclosures are strong and reliable. They are a great choice for many industries.

Corrosion Resistance

The Role of Alloying Elements

The excellent corrosion resistance of stainless steel stems from its unique alloy composition. Chromium is a crucial element.

When the chromium content in stainless steel reaches more than 12%, chromium reacts with the oxygen in the air to form an extremely thin and sturdy passivation film of chromium oxide on the surface.

This film can effectively block corrosive substances such as acids, alkalis, and salts from eroding the base metal, playing a role in preventing corrosion.

The Formation and Repair of the Passivation Film

Under normal environmental conditions, the passivation film on the surface of stainless steel is in a dynamic equilibrium state. Even if the film suffers from slight scratches or erosion during use, the chromium element in the stainless steel can quickly react with oxygen to regenerate a new passivation film and complete the self-repair process.

This enables the stainless steel to continuously maintain good corrosion resistance. However, when the external corrosive environment is too strong and exceeds the repair capacity of the passivation film, the stainless steel may be corroded.

Aesthetic and Professional Appeal

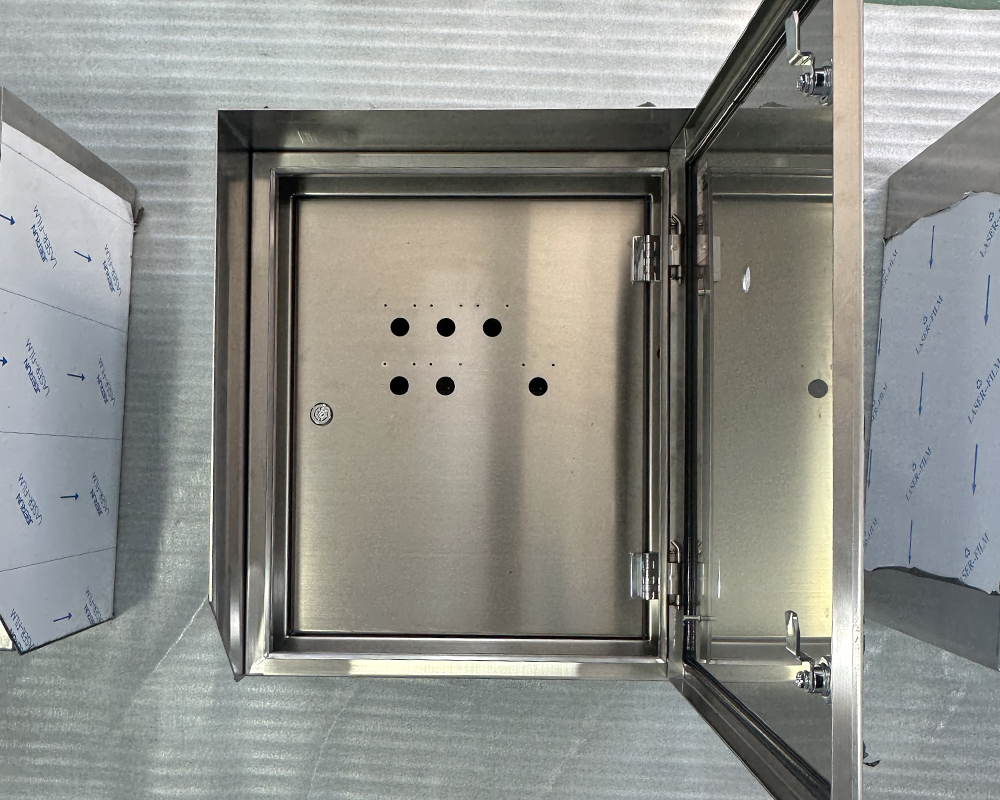

Modern and Sleek Design

Stainless steel enclosures look modern and stylish in industries. Their smooth metal panels give a clean and shiny finish. These enclosures fit well in factories or offices, making spaces look better.

Long-Lasting Appearance

Stainless steel enclosures stay looking good for years. Unlike other materials, they don’t rust or wear out easily. Even in tough places, stainless steel keeps its shine.

- In offices, stainless steel is chosen for its modern and shiny look.

It stays strong against weather, keeping its nice appearance.

- It needs little care, making it a smart and stylish choice.

Cost-Effectiveness

Lower Maintenance Costs

Stainless steel enclosures save money because they need less care. They are strong and don’t rust, so repairs are rare. In places with moisture or chemicals, other materials break down fast. Stainless steel stays tough and lasts longer.

The smooth surface of stainless steel is easy to clean. Dirt doesn’t stick much, so cleaning takes less time. This is very useful in food factories where cleanliness is very important. Using stainless steel enclosure helps companies save on cleaning costs.

Long-Term Value

Stainless steel enclosures cost more at first but last longer. They are strong and handle tough conditions better than other materials. This means fewer replacements and more savings over time.

Sustainability

Recycling Stainless Steel Enclosures

Stainless steel enclosures are great for the environment. They can be recycled when no longer needed. Most new stainless steel includes recycled materials. This means fewer natural resources are used compared to other materials.

Customizability

Customization of Dimensions and Shapes

In terms of dimension customization, stainless steel enclosures can be precisely designed according to the layout and size of the internal components of the device. Whether it is a large industrial control cabinet or a small precision instrument enclosure, manufacturers can offer tailor-made dimension solutions.

This not only ensures the reasonable installation and operation of the internal components of the device but also effectively saves space and improves the overall integration degree of the device.

Material Selection

he selection of materials is also an important part of customization. There are various types of stainless steel, such as 304 and 316, and each type of material has its unique performance characteristics.

Users can choose the most suitable stainless steel material according to different application requirements to ensure the long-term stable operation of the enclosure in specific environments.

Surface Treatment

The customization of surface treatment can further enhance the performance and appearance of stainless steel enclosures.

Common surface treatments include frosted finish, polishing, and brushing. In addition, special surface treatments can be carried out according to users’ needs, such as spraying anti-corrosion coatings and adding anti-static treatment, to meet the special requirements of different industrial environments.

>>> Read our detailed guide on : A Comprehensive Guide to Surface Treatment Methods

Functional Modules

The customization of functional modules is also a highlight of the customizability of stainless steel enclosures. Users can add various functional modules to the enclosure according to actual needs, such as ventilation openings, heat sinks, waterproof connectors, and mounting brackets.

Conclusion

The customizability of stainless steel enclosures enables them to fully meet the diverse needs of the industrial field.

Every aspect, from dimensions and materials to surface treatment and functional modules, can be customized according to the specific requirements of users, providing the most suitable protection and support for industrial devices.

This is also one of the important reasons why stainless steel enclosures are highly favored in the industrial field.

FAQ

1. Why is stainless steel better than other materials for enclosures?

Stainless steel doesn’t rust, handles heat, and lasts longer. It’s strong and needs little care, making it great for industries.

2. Can stainless steel enclosures be used outdoors?

Yes, they are great for outdoor use. Stainless steel resists rain, moisture, and sunlight. I’ve seen it stay strong and rust-free in wet or coastal areas. This makes it perfect for outdoor industrial jobs.

3. Are stainless steel enclosures customizable?

Yes, they can be made to fit any need. Industries can pick sizes, finishes, and features. I’ve seen custom enclosures used in factories and offices. They meet special needs and stay strong.

4. Do stainless steel enclosures require special maintenance?

No, they are easy to care for. Stainless steel resists dirt and rust. I’ve found that simple cleaning keeps them looking good and working well, even in tough places.

If you have any questions, you can leave a message by email : [email protected] and we will reply as soon as possible.