Biomass fuel leads the green way of sheet metal spraying

In the sheet metal production process, spraying is the last key process and it determines the appearance quality of products. Yinlu equips a professional automatic spraying production line. This production line uses biomass fuel as the working raw material. While ensuring the smooth progress of production, it also makes great contributions to environmental protection.

Protect the environment, starting from the sheet metal powder coating line

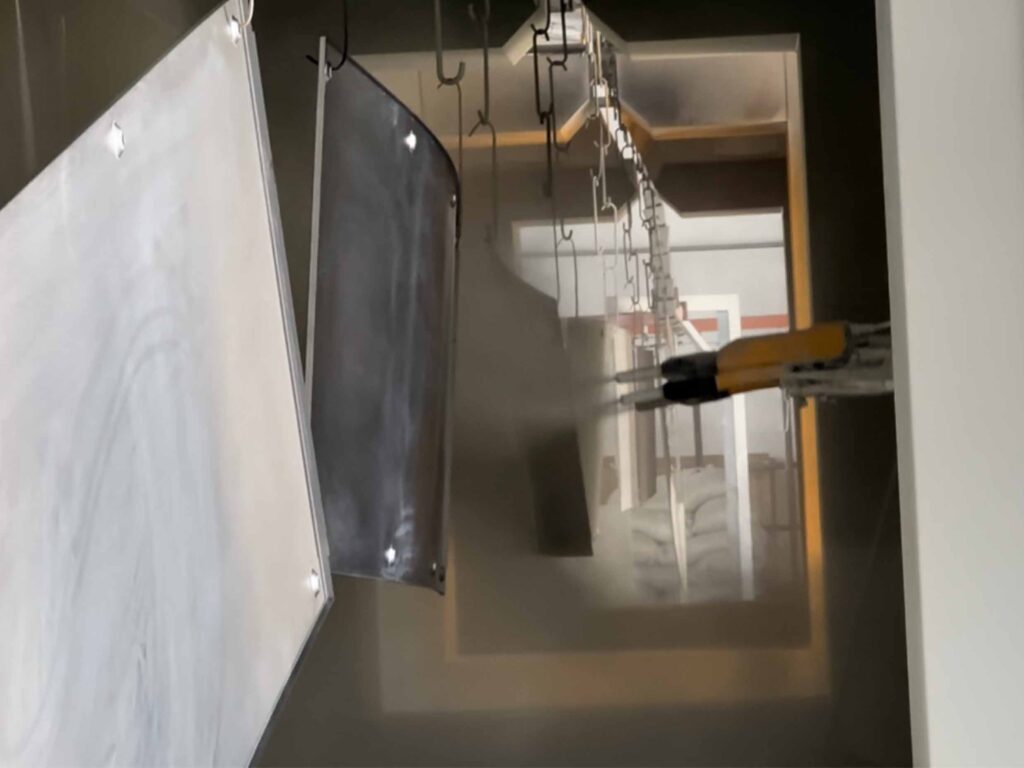

Figure NO.1 Sheet metal powder coating process and workshop display

Common types of biomass fuels

Biomass pellet

·People make it of crop straw, wood chips, bamboo chips and other biomass materials by crushing and compression molding.

·Regular shape, high density, easy to store and transport.

·High combustion efficiency and relatively few pollutants.

Biomass block fuel

·It is usually cut or compressed into chunks by wood, straw and other biomass materials.

·Compared with biomass particles, bulk fuel has a larger volume, but it also has a certain stability.

·Suitable for some large combustion equipment.

Characteristics of biomass fuel

Renewable

·Solar energy, which is fixed by plant photosynthesis, is a sustainable energy source.

·Reduced dependence on limited resources compared with fossil fuels.

Low pollution

·Plants can absorb the carbon dioxide produced during combustion to achieve carbon cycling and it has less impact on the greenhouse effect on the environment.

·Compared with traditional fuels such as coal, sulfur content, nitrogen oxides and particulate matter emissions are lower.

Widely distributed & Convenient storage

·Biomass resources are rich, widely distributed in rural and agricultural areas, can be used locally to reduce transportation costs.

·Biomass fuel can be stored in a dry environment for a long time and is not easy to volatilize and leak.

Figure NO.2 Biomass Fuel Display

Application in automatic spraying line

Provide heat source for drying

·In the automatic spraying line, we need to dry the workpiece after spraying to remove moisture and make the paint cure quickly. When we burn biomass fuel, it can release a lot of heat energy. We can transfer this heat energy to the drying equipment through heat transfer to provide the required temperature for the drying of the workpiece.

Heating coating equipment

·In the automatic spraying line, we need some painting equipment to maintain a certain temperature to ensure the performance and spraying effect of the paint. We can use biomass fuel to heat these painting equipment to maintain the painting equipment within the appropriate operating temperature range.

Drive conveyer

·The conveying device in the automatic spraying line needs power to drive. We can convert biomass fuel into mechanical energy through the heat energy generated by combustion to provide power for the conveying device.

Overview

·In short, the automatic spraying line uses biomass fuel, which can reduce greenhouse gas emissions, reduce dependence on fossil fuels, reduce atmospheric pollutants, achieve comprehensive utilization of resources, and promote sustainable development. The application of biomass fuel provides a feasible way for us to protect the ecological environment while pursuing industrial development.

Please visit our company website [www.yinlu-sheetmetal.com]for more details.