JFY PM9 150T Press Brake

JFY established in 1990. It is a wholly-owned subsidiary of the German TRUMPF Group. Specializes in the research, development, manufacturing and sales of CNC machine tools.Mass-produces products such as CNC punching machines, CNC laser cutting machines, CNC bending machines, and CNC shearing machines. Produces more than 2,000 CNC machine tools annually. Provides automated processing solutions for multiple industries.

International brands of press brake

·TRUMPF ·AMADA ·BYSTRONIC

·SALVAGNINI ·LVD ·PRIMAPOWER·

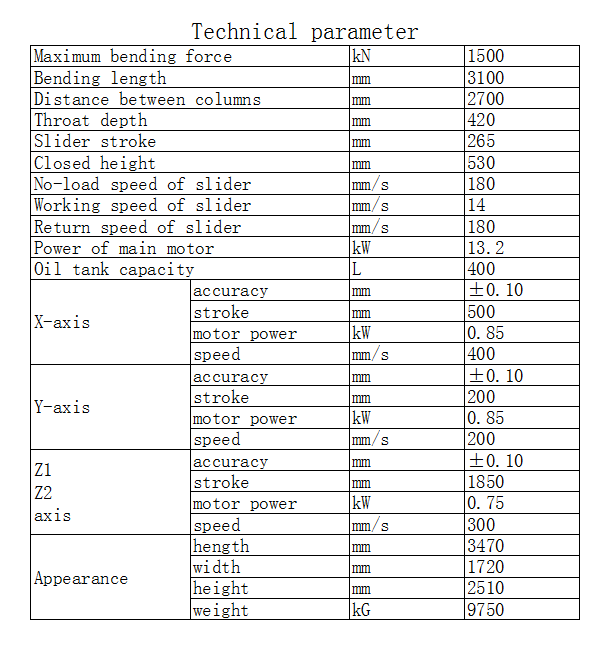

Technical parameter

Figure NO.1 JFY PM9 150T Technical Parameter

Product Features

High precision machining

·Equipped with an advanced numerical control system, it can precisely control parameters such as bending angle and stroke to ensure the stability and consistency of processing precision.

·Adopting high-quality mechanical parts and transmission devices reduces mechanical errors and gaps and further improves the bending precision.

Efficient production capacity

·It has a relatively large bending pressure. The pressure of 150T can easily handle sheet metal bending of various thicknesses and strengths, improving production efficiency.

·The fast stroke speed and action response shorten the processing cycle and can meet the needs of large-scale production, providing strong support for enterprises to improve production efficiency and reduce production costs.

Good operating system and man-machine interface

·The numerical control system is easy to operate and has a friendly interface. Operators can quickly get started, reducing training time and operation difficulty.

·It has intelligent operation functions such as automatic programming and graphic simulation, helping operators better understand and master the bending process and improve the accuracy and efficiency of processing.

Figure NO.2 Man-machine interface display

Strong stability and reliability

·The fuselage structure is reasonably designed. It adopts high-strength steel and advanced welding technology to ensure the stability and rigidity of the fuselage. It is not easy to deform and vibrate during long-term use, ensuring the long-term stability of bending precision.

·Select high-quality electrical components, hydraulic components and other key parts to ensure the reliability and durability of the equipment, reduce the failure rate of the equipment and reduce maintenance and repair costs.

Flexible bending function

·It can realize various bending methods, such as angle bending and arc bending, to meet the bending needs of workpieces with different shapes and requirements. For the processing of sheet metal parts with complex shapes, it has strong adaptability and flexibility.

·The back gauge device is convenient to adjust and has high precision. It can quickly and accurately adjust the position of the sheet to ensure the accuracy and consistency of bending.

Energy saving and environmental protection

·It adopts advanced energy-saving technology and can effectively reduce energy consumption during equipment operation, meeting the energy conservation and environmental protection requirements of modern industry.

·The hydraulic system is reasonably designed, reducing the leakage and waste of hydraulic oil and reducing environmental pollution.

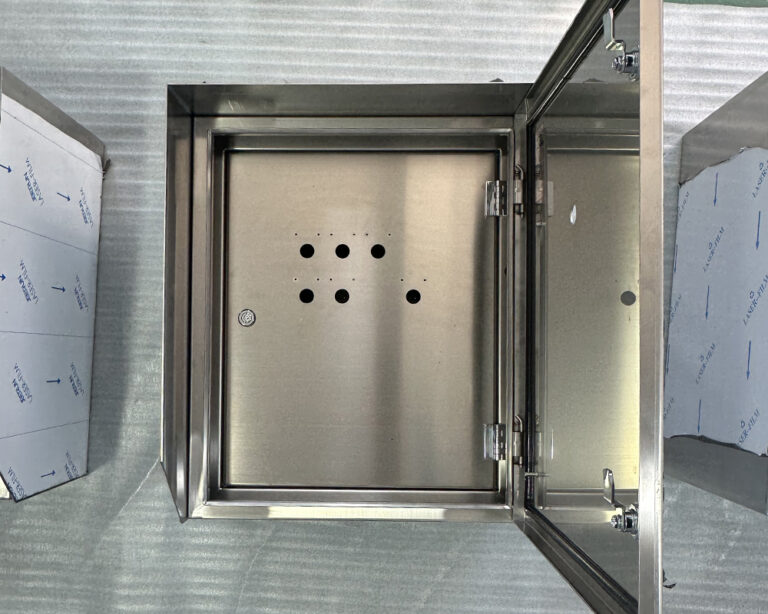

Figure NO.3 JFY PM9 150T

Machining effect

This JFY PM9 bending machine has already become our main equipment for bending work. No matter the size of the product, it can perform this task excellently. The advanced technology and high-quality structure of this machine ensure precise and efficient bending operations every time. Its friendly user interface and reliable performance make it an important tool in our production process. We believe that in the days to come, this JFY PM9 bending machine will continue to play an important role in our bending work and help us create more high-quality products and contribute more to the development of the enterprise.

We are equipped with a total of five CNC bending machines. If you want to know more about our equipment,

you can visit our website www.yinlu-sheetmetal.com for more details.

Figure NO.4 Bending effect display