Sheet Metal Prototype Fabrication Services

- Prototype sheet metal manufacturer

- Sheet metal prototype instant quote

- Professional design

- Low MOQ

Custom Sheet Metal Prototype Fabrication

If you are considering looking for a reliable sheet metal prototype manufacturer, then Yinlu is definitely a choice you can’t afford to miss or overlook.

Yinlu was founded in 1993. After 31 years of development, we have established cooperative relationships with more than 1,000 customers, including well-known international enterprises such as Siemens, ABB and Panasonic.

Our products cover a very wide range and are applied in multiple industries, such as heavy industry, food, electric power and new energy.We provide a full-process, one-stop sheet metal prototype design service covering design, cutting, bending, welding, grinding, spraying and assembly.We are more than willing to develop business together with your company.

Table of Contents

FAQ For Sheet Metal Fabrication Prototype

- Betty

What is sheet metal prototype design

This is a process to verify whether the design concept of sheet metal products is feasible.

It requires repeated design, production, verification and optimization.It can also be simply understood as a sample, and we are responsible for transforming concepts into real products.

Through sheet metal prototype design, problems in the design can be discovered in a timely manner and then optimized.

Discovering and solving existing problems before mass production can avoid a large number of defective products after large-scale production.

Therefore, sheet metal prototype design reduces production costs and risks to a certain extent.

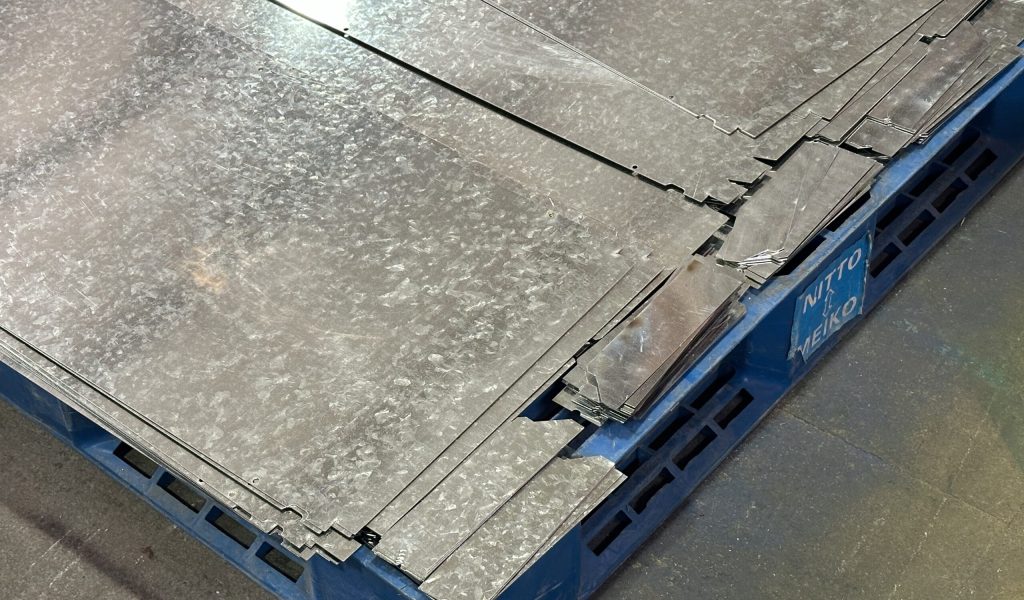

Figure No.1 Sheet metal prototype fabrication case

What's the basic process of sheet metal prototype design

- Determine the usage and the expected functions of the user’s sheet metal products.

- Professional designers will conceive the general form and the overall structural layout of the product according to the customer’s needs.

- Precisely plan all the dimensions of the sheet metal parts, including details such as length, width, height and the assembly dimensions among different parts. Meanwhile, reasonably set the tolerance range based on the processing technology and material characteristics.

Figure No.2 Sheet metal parts

- Based on the shape and structural requirements of the product, carefully design parameters like the bending positions, bending angles and bending radii of the sheet metal.

Select appropriate connection methods for sheet metal parts. Common ones include welding, riveting and bolt connection. Determine which specific connection method or combination to adopt according to the requirements of the product in terms of strength, sealing performance and convenience of disassembly.

For some products with relatively low strength requirements, in order to reduce transportation costs, we can provide free design of disassembly and assembly structures. - Plan the surface treatment process, such as powder coating, electroplating and wire drawing, according to the usage scenarios and appearance requirements of the product. This can not only improve the aesthetics of the product but also enhance its corrosion resistance and other properties.

Figure No.3 Automatic powder coating line

- Use professional sheet metal prototype design software, such as SolidWorks and AutoCAD, to build a three-dimensional digital model of the sheet metal product in accordance with the detailed design content.

- Advanced equipment like laser cutting machines and CNC bending machines to perform operations such as cutting and bending on the sheet metal materials.

Figure No.4 Laser cutting

- Conduct various functional tests on the fabricated sheet metal prototype to check whether it can meet the initially set functional requirements.

Evaluate the performance of the prototype in aspects like strength, stability and durability.

Based on the problems discovered during the testing process, such as unreasonable structures, difficult-to-implement processes and substandard performance, make corresponding optimization and adjustments to the design. - Then make the prototype again and conduct tests until the prototype basically meets the project requirements.

How to choose materials according to the functions of sheet metal prototype

Figure No.5 Sheet metal fabrication raw materials(galvanized sheet)

Which materials can be used for sheet metal manufacturing

Common sheet metal processing materials include carbon steel, stainless steel, galvanized steel, aluminum, aluminum alloy, copper and so on.

No matter what sheet metal processing materials are used, Yinlu has the ability to do a good job in sheet metal prototype design that satisfies customers.

>>> Please continue reading

What are the benefits of cooperating with sheet metal prototype manufacturers like Yinlu

We possess advanced production equipment and technologies.

Equipment such as CNC bending machines, laser cutting machines and plate shears are all from well-known brands like AMADA.

We have a comprehensive ISO 9001 quality management system. From the procurement of raw materials to the delivery of finished products, strict quality inspections are carried out in every link.

How to get a sheet metal prototype instant quote

Yinlu is fully capable of providing you with customized sheet metal prototype processing services.

However, we need to know the specific usage of the sheet metal prototype.

For example, whether the usage environment is indoors or outdoors, as these will involve special requirements such as waterproofing, dustproofing and corrosion resistance of the product.

Providing precise dimensional specifications will help us calculate the costs and offer you the most cost-effective sheet metal prototype design solutions.

Then, if you have certain requirements for the appearance of the product, such as a specific color, spray painting, powder coating or other surface finishes, Yinlu will meet your needs as long as you have the requirements.

Clarify the type and thickness of the processing materials to be used.

If you don’t have a definite idea about the choice of materials, Yinlu can still help you screen the most suitable ones.

These are basically the basic information about the sheet metal prototype product that we need to know. Then we can provide you with a sheet metal prototype instant quote.