Table of Contents

What is electrical enclosure?

An electrical enclosure is a relatively enclosed structure, usually made of metallic or non-metallic materials.

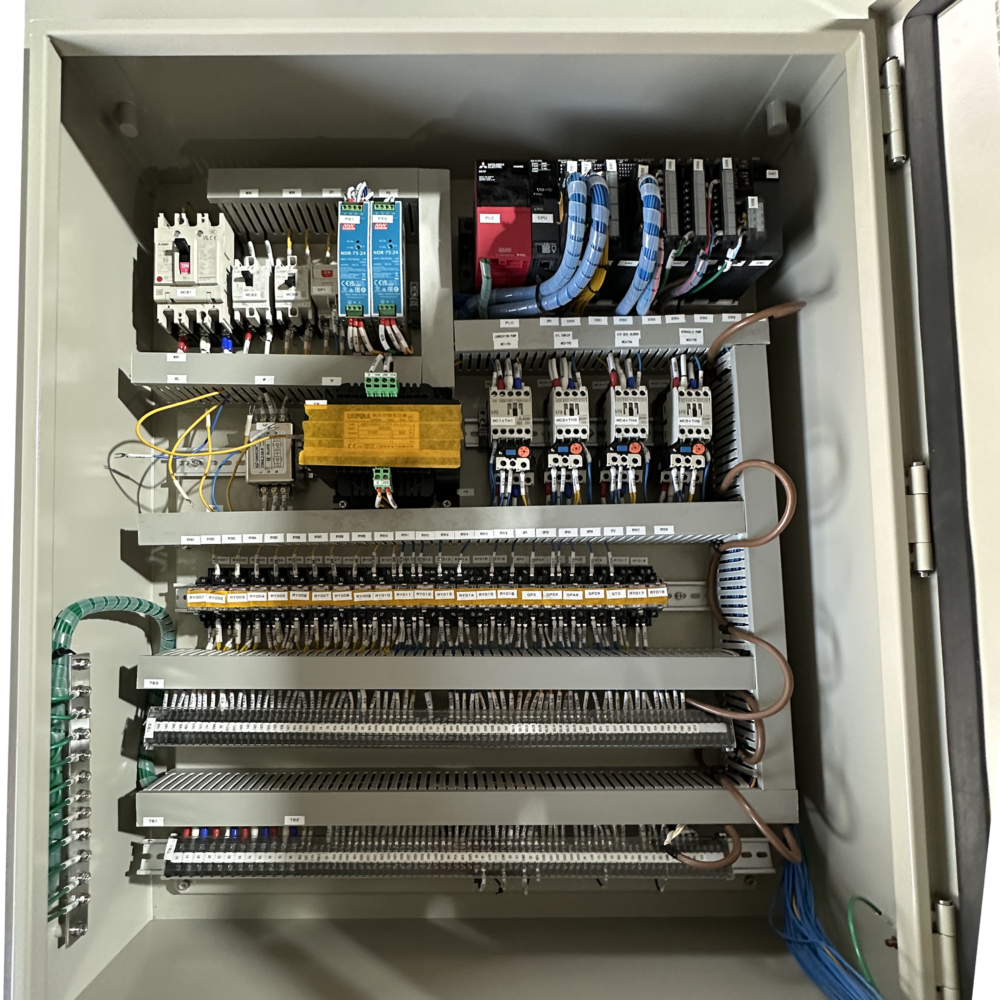

Inside it, there are components like mounting brackets, wire ducts, and terminal blocks, which are used to install and fix various electrical devices, such as circuit breakers, contactors, relays, frequency converters, PLC, etc.

It also provides physical protection and a proper operating environment for these devices.

- Betty

Electrical Enclosure Function & Structure

- Protecting electrical equipment

- Ensure personnel safety

- Organize and regulate electrical wiring

Electrical enclosure classification

By mounting type

- Wall-mounted electrical enclosure

It is suitable for use in places with limited space, such as small workshops and offices. It can save floor space and facilitate the wiring connection on the wall. - Floor-standing electrical enclosure

It is applicable to scenarios that require larger space, stable support and centralized management of electrical equipment, such as in industries, data centers, commercial buildings, etc. - Flush-mounted electrical enclosure

It focuses on integrating with the environment, optimizing space utilization and meeting the requirements of special industries, and is commonly seen in commercial buildings, home intelligent systems, medical fields and other places.

By protection level

It is widely used worldwide to define the protection levels of various electrical equipment and enclosures like electrical cabinets.

It is expressed in the form of two digits plus a letter (sometimes no letter)

- First number (dustproof grade)

0-6:Indicates the level of preventing solid foreign bodies from entering. The larger the number, the stronger the protection ability. - Second number (waterproof grade)

0-8:Indicates the level of preventing water intrusion, the larger the number, the stronger the waterproof ability. - IPXXA

Based on the dustproof level indicated by the first number, an additional protection against touching the electrified parts through the protective openings is provided. Even if foreign objects get in, they won’t be able to touch the electrified parts. IPXXB

Based on the waterproof level indicated by the second number, an additional protection against touching the electrified parts through the protective openings is provided. Even if water flows in, it won’t be able to touch the electrified parts.

By application evvironment

It is applicable to various scenarios where electrical equipment needs to be installed outdoors, such as communication base stations, outdoor monitoring systems, streetlight control systems, etc.

Weatherproof electrical enclosure

It places more emphasis on the protection against meteorological factors like wind and rain. Its sealing performance, waterproof structure, and windproof design are more elaborate.

Explosion-Proof electrical enclosure

It is specifically designed for dangerous environments where flammable and explosive substances exist, such as petrochemical plants, underground coal mines, gas stations, etc.

By material

- Metallic Material(steel,aluminum,etc.)

High strength

Excellent conductive & electromagnetic shielding

Good heat dissipation & fire protection - Non-metallic Material(plastic, fiberglass, etc.)

Strong insulation and anti-corrosion properties

Light weight, easy to carry and install

Good heat insulation, radiation protection & weather resistance easy to customize.

Commonly used electrical enclosure box materials

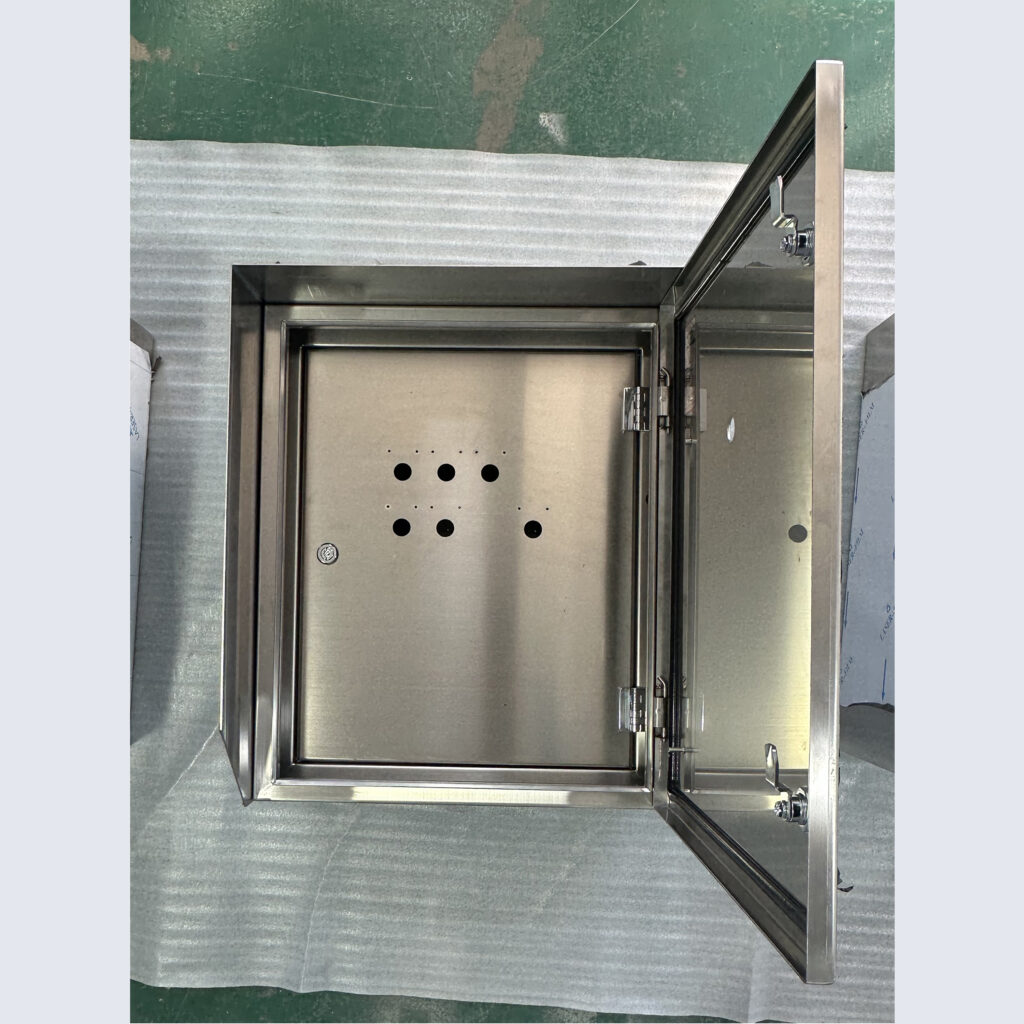

Stainless steel enclosures, thanks to their durability, corrosion resistance, and excellent formability, have become the preferred choice in the field of industrial equipment. They stand out in harsh environmental scenarios .

Aluminium electrical enclosure

Aluminum alloy enclosures have become a popular choice in the field of electronic equipment due to their lightweight yet high-strength characteristics and excellent thermal conductivity. They excel in application scenarios where good heat dissipation and strict control over equipment weight are required.

Conclusion

If you would like to know more about electrical cabinets you can contact us or read more on our website yinlu-sheetetal.com we are happy to help and we are also a specialist manufacturer so you can

get a quote for free!