VFD Enclosure Supplier

- Yinlu provides a variety of VFD solutions.

- Professionally Solve Selection Dilemmas

- Provide Practical Suggestions

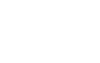

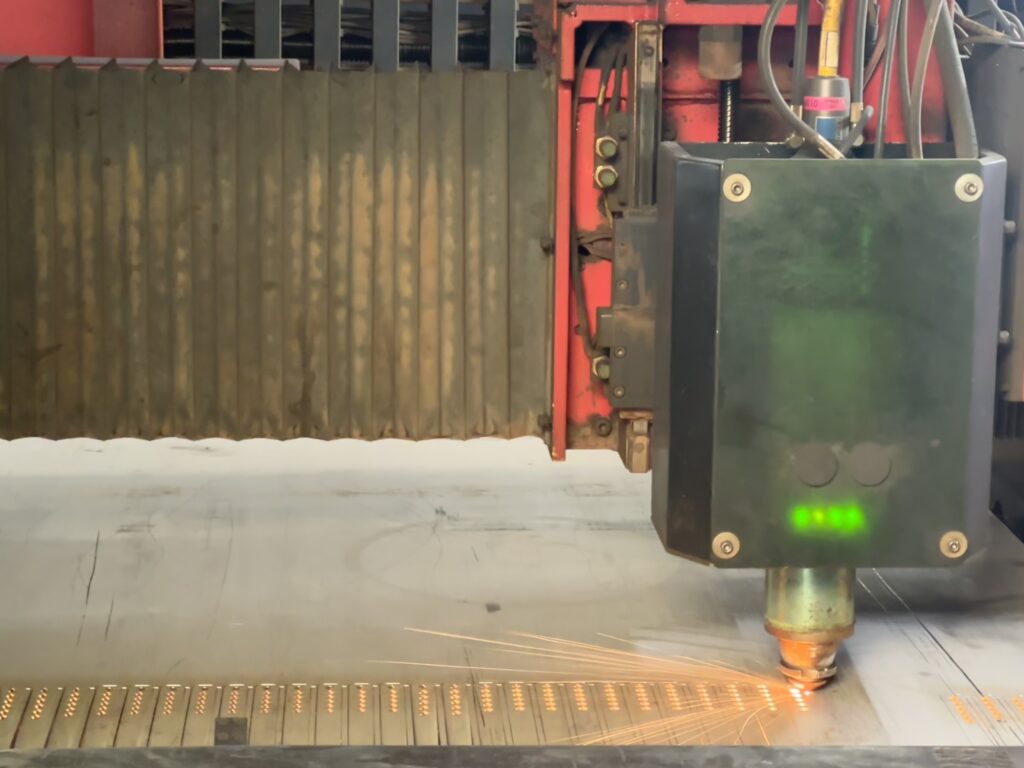

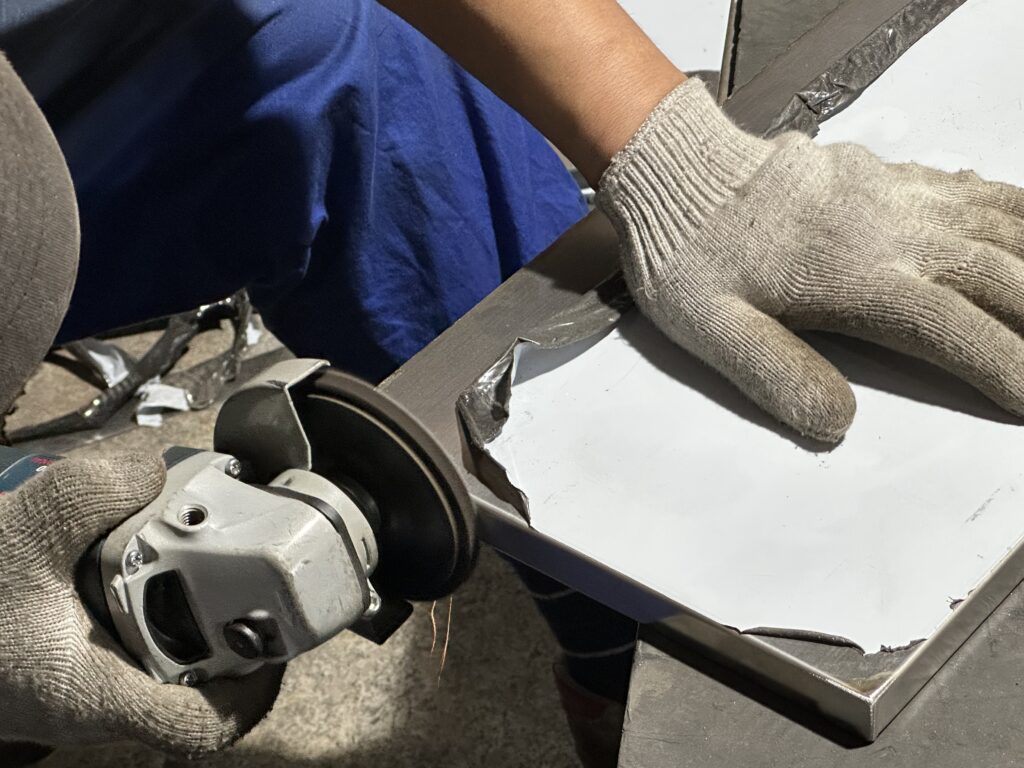

VFD Enclosure Fabrication Capacity

Table of Contents

How to Select an Appropriate VFD Enclosure

- Betty

A suitable VFD Enclosure can ensure the stable operation of the Variable – Frequency Drive (VFD) and extend the equipment’s lifespan.

But how can you find the most suitable VFD Enclosure?

This article will offer you a comprehensive guide and practical purchase suggestions.

>>> Keep Reading

What is a VFD enclosure

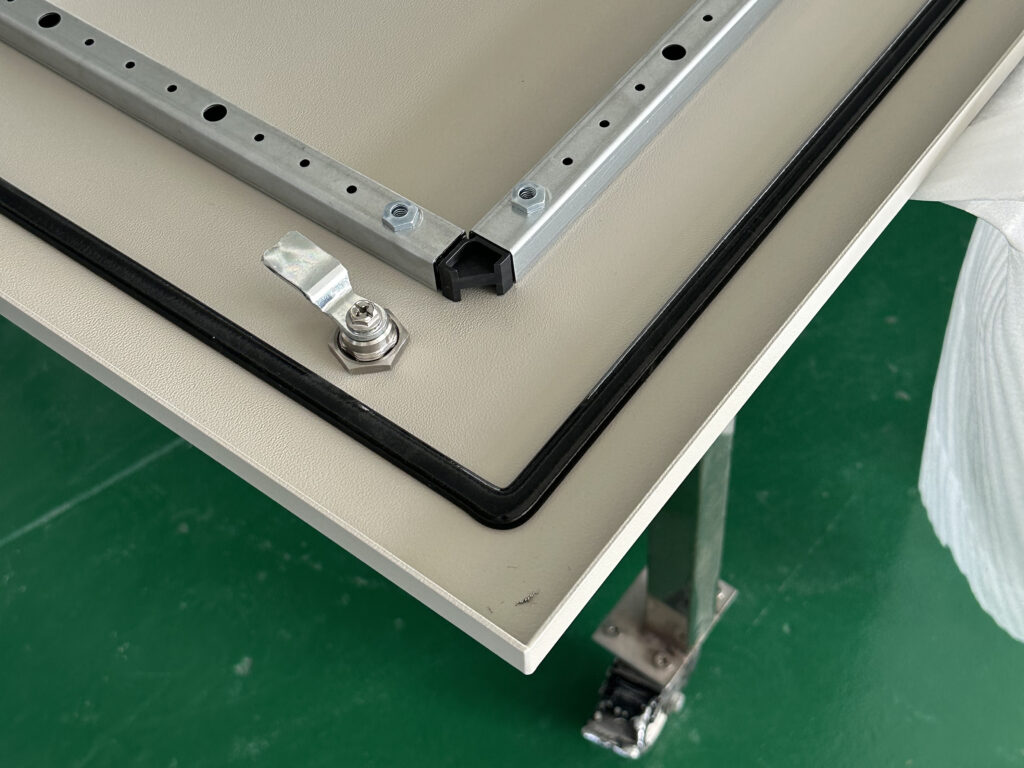

A VFD Enclosure is a protective device specifically designed to safeguard the Variable Frequency Drive (VFD).

People widely use VFD Enclosures in fields such as industrial automation, manufacturing, energy, and transportation. They are crucial for ensuring equipment reliability.

If your operating environment is a dry, dust-free indoor space, an IP20 rating should meet your protection needs.

For indoor environments with more dust or humidity, the cabinet typically achieves an IP54 rating to block out moisture and dust.

In outdoor, dusty, humid, or potentially water-sprayed environments, our VFD Cabinet reaches an IP65 rating, offering complete dust protection and resistance to low-pressure water jets, making it suitable for outdoor or harsh industrial settings.

For outdoor environments exposed to strong water jets, seawater, or heavy rain, we provide an IP66 rating, which can withstand powerful water sprays and suits extreme outdoor conditions.

If your environment involves potential short-term immersion in water (such as temporary flooding), we generally recommend an IP67 rating, which ensures full dust protection and can handle brief water submersion.

Advantages and Disadvantages of Different Materials

Common materials for VFD Enclosure include metallic and non – metallic materials.

Common metallic materials are cold – rolled steel sheets, stainless steel, aluminum alloy, etc.; non – metallic materials include polycarbonate, etc.

Cold rolled steel: They offer high cost – effectiveness and are mostly suitable for general industrial environments.

Stainless steel: This material has strong corrosion resistance and is suitable for use in harsh environments.

Aluminum alloy: It is lightweight and has good heat dissipation, so it is used more frequently in high – temperature environments.

Polycarbonate: It has a transparent design. This material is generally used in situations where it is necessary to observe the internal equipment at any time.

Which Certifications Are Necessary

Selecting the appropriate certifications is crucial for the design and manufacturing of VFD Enclosures.

Whether they are international standards (such as IEC, UL), industry – specific certifications (like ATEX), or environmental protection certifications (such as RoHs), these certifications serve as important guarantees for product quality and market access.

IEC (International Electrotechnical Commission) Standards

IEC 61439 (Low – voltage switchgear and controlgear assemblies): This is the core standard for VFD Cabinet, covering requirements in aspects such as design, safety, and performance.

IEC 60529 (Degrees of protection provided by enclosures – IP Code): Defines the dust – proof and water – proof ratings of equipment.

CE (Compulsory Certification in the European Union)

For VFD Cabinet, it needs to meet the EN 61439 series of standards.

UL Certification (For the US Market)

UL 508A (Standard for Industrial Control Equipment):

Applies to VFD Cabinet in the North American market.

UL 50 (Standard for Enclosures for Electrical Equipment):

Defines the protection ratings of enclosures and their environmental adaptability.

Benefits of Certifications

Ensure Safety: Prevent electrical, mechanical, and environment – related hazards.

Enhance Reliability: Adapt to various environmental conditions and ensure long – term stable operation.

Meet Market Compliance: Comply with laws, regulations, and industry entry requirements.

Optimize Function and Performance: Improve energy efficiency and compatibility.

Reduce Risks and Costs: Minimize failure rates and legal disputes.

Yinlu is committed to providing high quality and high standard products.

If you have any related needs, you can contact us at any time.