PLC Cabinet & PLC Enclosure

- High protection level design

- Fully customized solutions

- 30 years of industry experience

PLC Cabinet Series Product

A PLC cabinet ( pogrammable logic control cabinet ), is an electrical control cabinet for installing and protecting the programmable logic controller (PLC) and related equipment.

Table of Contents

Everything You Need To Know About PLC Cabinets

- Betty

What is a PLC Cabinet

It is an enclosure device used to install and protect programmable logic controllers (PLCs) and their related electrical equipment such as power supplies, relays, terminal blocks, etc. Usually made of metal materials like cold – rolled steel plates, stainless steel, or aluminum alloy, it features a high protection level, good heat dissipation performance, and electromagnetic interference shielding ability.

The PLC cabinet is used to achieve various functions and plays a crucial role in industrial automation and various control systems.

We also have an article that specifically explains how to build a PLC cabinet. You can click to read it.

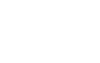

Figure No.1 Industrial electrical control cabinet

Main function

- Protective equipment

- Electromagnetic interference shielding

- Heat dissipation management

- Centralized management

Material selection of plc cabinet

Common Material Types

Cold – rolled steel plate: It has high strength and good durability. The cost is relatively low, offering high cost – performance. Its surface is smooth, making it easy to spray or apply plating treatment.

Stainless steel: It has excellent corrosion resistance, being suitable for humid and corrosive environments. It also has high strength and durability. It has an aesthetic appearance and is easy to clean.

Figure No.2 Stainless Steel

Galvanized steel plate: It has a galvanized surface, and its corrosion resistance is better than that of ordinary cold – rolled steel plates. The cost is moderate, providing high cost – performance.

Figure No.3 Galvanized steel

Aluminum alloy: It is lightweight, facilitating handling and installation. It has good heat dissipation performance. Its corrosion resistance is relatively good, though not as good as that of stainless steel.

Polycarbonate: It is lightweight and is transparent or semi – transparent, which makes it convenient to observe the internal equipment. It has good impact resistance. Its corrosion resistance is relatively good, but its high – temperature resistance is limited.

Figure No.4 Polycarbonate

Fiberglass Reinforced Polyester, FRP: It is lightweight and has extremely good corrosion resistance. It has good insulation properties, making it suitable for high – electromagnetic – interference environments. It is resistant to ultraviolet rays, making it suitable for outdoor use.

In Yinlu, when it comes to the materials for PLC cabinets, we often choose metal materials such as cold rolled steel sheets, stainless steel sheets, and aluminum alloys. We offer a wide variety of metal materials for selection.

PLC cabinets made of metal materials feature high strength, excellent electromagnetic interference resistance, outstanding heat dissipation, strong corrosion resistance, good processing performance and appearance, as well as cost – effectiveness.

How to choose the most suitable material

Selecting the appropriate material requires comprehensive consideration from multiple dimensions.

For example, factors such as the operating environment, mechanical strength, heat dissipation requirements, weight, cost, and appearance need to be taken into account.

These are the keys to ensuring the performance, reliability, lifespan, and cost – effectiveness of the PLC Cabinet.

The environment is relatively stable, without extreme temperatures, humidity, or corrosive substances.

In this kind of environment, high humidity can cause metal to rust and electrical equipment to get damp.

Stainless steel or glass – fiber – reinforced polyester is recommended.

Corrosive environment:

There are chemical substances in the environment that may cause material corrosion.

Stainless steel, glass – fiber – reinforced polyester, and polycarbonate are recommended.

High – temperature environment:

The ambient temperature is relatively high, which may cause materials to deform or equipment to overheat.

Stainless steel, aluminum alloy, and cold – rolled steel plates are recommended.

Outdoor environment:

Being exposed to the natural environment, it may be affected by ultraviolet rays, rain, dust, etc.

Stainless steel, glass – fiber – reinforced polyester, and galvanized steel plates are recommended.

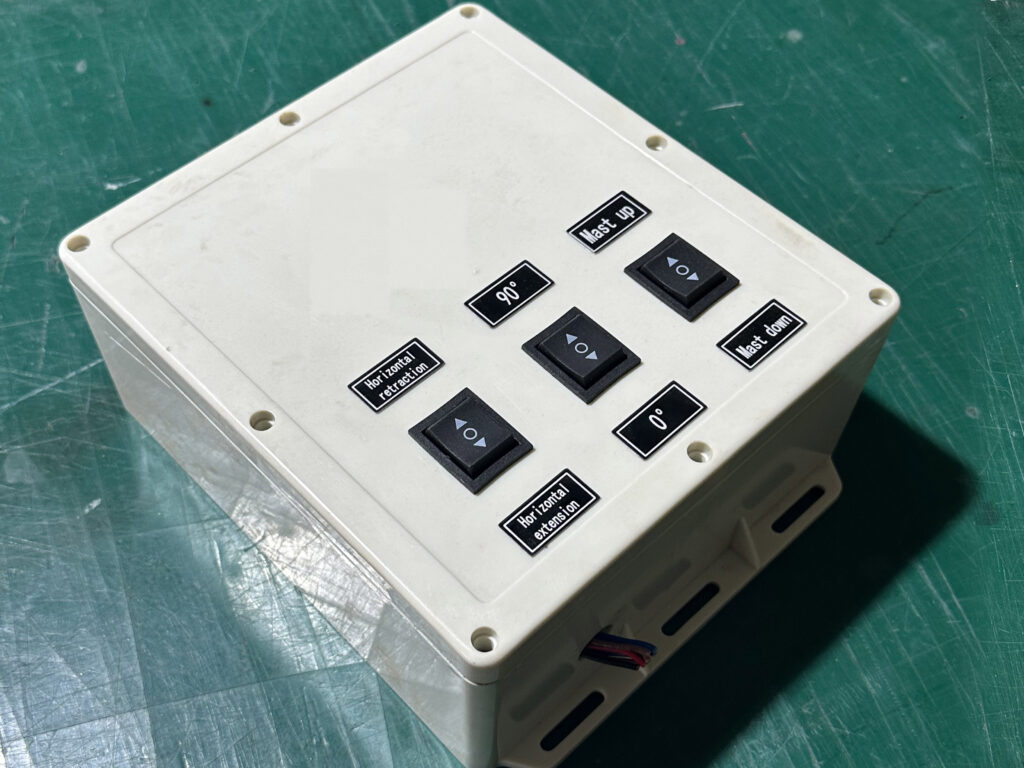

Figure No.5 Outdoor Environment

High – electromagnetic – interference environment:

The strong electromagnetic interference in the environment can affect the operation of PLCs and other electrical equipment.

Cold – rolled steel plates, stainless steel, and aluminum alloy are recommended.

Design and structure of plc cabinet

We offer fully customized PLC cabinet design services. We adjust the dimensions, materials, layout, and functions according to your specific requirements to ensure a perfect fit for your project.

Common PLC Cabinet dimensions

The height of small – sized PLC cabinets usually ranges from 400 to 600mm, the width is 300 – 500mm, and the depth is 200 – 350mm. They are generally suitable for scenarios with relatively simple control functions. Inside, they are equipped with a small number of DIN rails for installing PLC modules and other basic control components.

The height of medium – sized PLC cabinets is generally 800 – 1200mm, the width is 600 – 800mm, and the depth is 400 – 600mm. They are suitable for medium – scale automated control systems. Besides DIN rails, there is more space for wiring and installing wire ducts.

The height of large – sized PLC cabinets can reach 1800 – 2200mm, the width is 800 – 1200mm, and the depth is 600 – 800mm. These large – sized cabinets are often applied in large – scale industrial projects.

Custom PLC Cabinet design

Dimensions: We can customize the height, width, and depth according to the installation space and the number of devices. Yinlu can design any non-standard dimensions!

Materials: We have a variety of options for the selection of industrial plc enclosure materials, such as cold-rolled steel plates, stainless steel, etc.

Layout: We customize the internal layout according to the number of devices and wiring requirements of the specific project of the customer, optimizing the space utilization to the greatest extent.

Heat Dissipation Design: We customize the vents, fans, or air conditioning systems according to the heat dissipation requirements.

Protection Level: We customize the IP protection level according to the usage environment of the plc control cabinet. For example, in outdoor environments, we can provide an IP65 protection level to ensure a certain degree of dust and water resistance.

Appearance: Yinlu has rich surface treatment technologies, such as options for appearance customization like spraying, wire drawing, and color, enhancing the overall aesthetics.

Through the customized services provided by Yinlu, you can obtain a plc cabinet that fully meets your needs.

PLC cabinet industry standards and certification

In the numerous application fields of plc cabinets, when designing and manufacturing them, one needs to follow a series of strict industry standards and certifications, such as IEC, NEMA, UL, and IP protection levels. These standards not only ensure the quality, safety, and reliability of the equipment but also assist users in choosing the most suitable products for different application environments.

IEC Standards

The IEC standards are among the most widely followed standards globally, especially in the field of electrical and electronic equipment.

IEC 61439 Standard: It applies to low – voltage switchgear and controlgear assemblies. This standard sets out the structure, performance testing, and safety requirements of the plc cabinet, ensuring the safety and reliability of the equipment. It is suitable for most industrial environments.

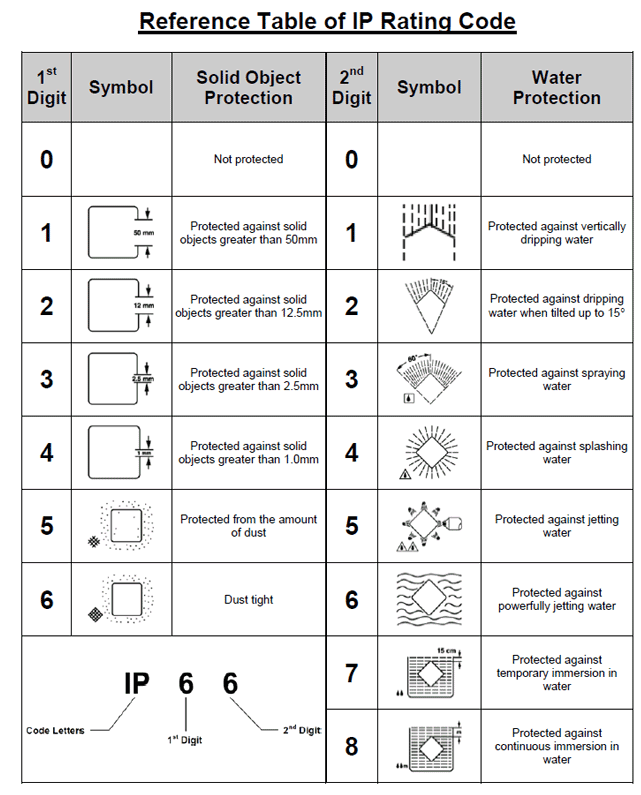

IEC 60529 Standard: It applies to the IP protection level standard and defines the equipment’s protection level against water and dust from the outside world.

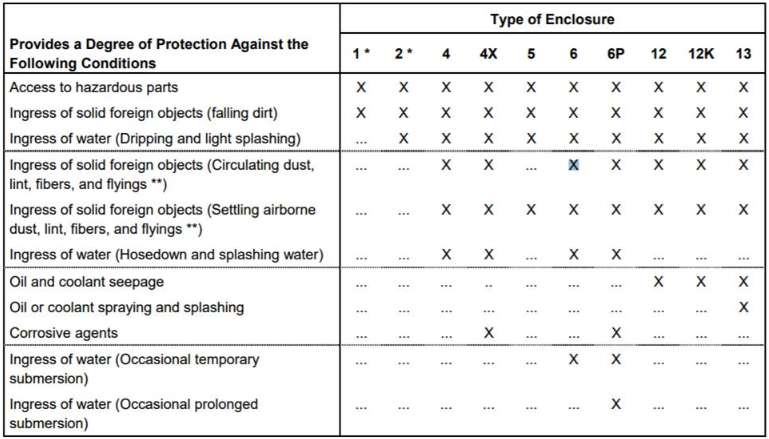

NEMA Standards

The common NEMA 4/4X is applicable to dustproof, waterproof, and corrosion resistant requirements. It is suitable for plc cabinets used outdoors or in harsh environments, ensuring the long – term stable operation of the equipment in harsh conditions.

Figure No.6 NEMA Standard

The IP level is one of the most frequently followed standards in PLC Cabinets and is applicable to the global market.

IP54: It is dustproof and splashproof, suitable for general industrial environments.

IP65: It is completely dustproof and waterproof, suitable for outdoor or harsh environments.

Figure No.7 IP Rating Standard

UL certification is one of the most authoritative safety certifications globally issued by Underwriters Laboratories in the United States.

UL 508A: Standard for Industrial Control Equipment applies to electrical equipment such as industrial control panels and PLC cabinets.

UL 50: Standard for Electrical Equipment Enclosures sets out the requirements for the structure, materials, and performance of electrical equipment enclosures, and applies to the enclosure design of PLC cabinets.

>>> Tips

Differences between UL Certification and Other Certifications

UL vs CE:

UL: Primarily applies to the North American market, with a focus on electrical safety.

CE: Mainly applies to the European market, covering safety, health, and environmental protection requirements.

UL vs CSA:

UL: It is a U.S. standard and globally recognized.

CSA: It is a Canadian standard and mainly used in the Canadian market.