Table of Contents

Stainless steel enclosure

Yinlu, as a highly professional manufacturer in the field of sheet metal fabrication,

has accumulated rich processing experience after 30 years of development.

Especially in the application of stainless steel materials, we start from every key link such as design planning, process selection and quality control to provide you with high-quality stainless steel enclosure products in an all-round.

- Betty

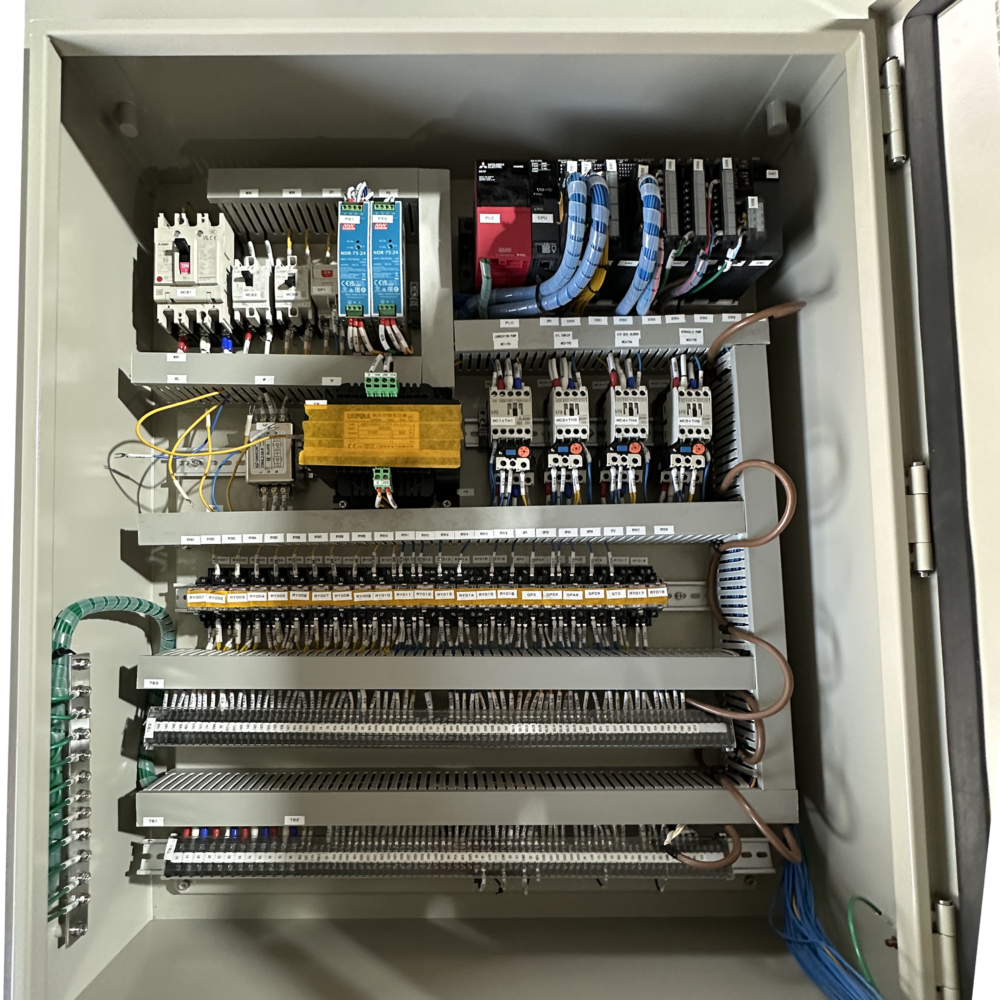

Yinlu Stainless Steel Enclosure Series

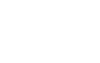

Stainless steel junction box

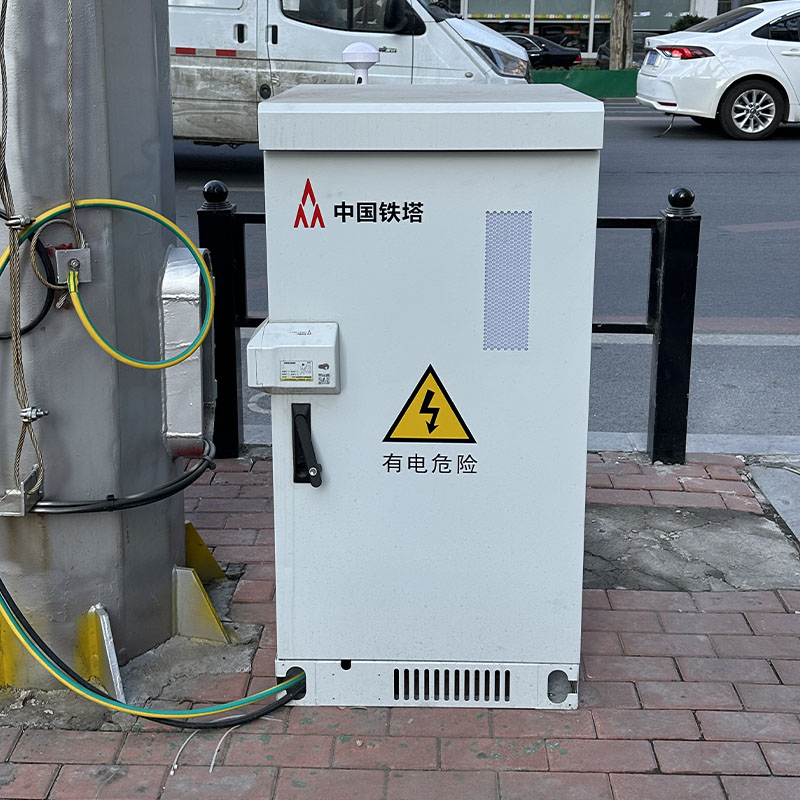

Double-door

Stainless steel enclosure

Wall mount with window

Stainless steel enclosure

How Yinlu provide solution for your stainless steel encolsure

You can send us your drawings, of course, you can also tell us your product needs such as size, internal structure, material, etc. Our professional design team will provide you with exclusive solutions for your stainless steel enclosure.

Multiple applications of Yinlu stainless steel enclosure are widely seen in various industries.

We have a variety of stainless steel enclosure types, such as indoor, outdoor, waterproof, dustproof, weatherproof, explosion-proof, etc.,.

You can choose according to your actual needs

What is stainless steel

Stainless steel is a type of steel that is relatively stable and not prone to rusting in weakly corrosive media such as the atmosphere and fresh water. The key to its corrosion resistance lies in the fact that it contains a certain amount of chromium (Cr) elements, usually with a content of not less than 10.5%.

When chromium comes into contact with oxygen in the air, a thin yet dense chromium oxide (Cr₂O₃) protective film will form on the surface of the steel,

which can effectively prevent external oxygen, moisture and other corrosive media from further eroding the interior of the steel, thus endowing stainless steel with good corrosion resistance.

Classification of stainless steel

Austenitic stainless steel

In sheet metal fabrication, common austenitic stainless steel grades include 304, 316, etc.

-Excellent corrosion resistance

–Good toughness and ductility

-Nonmagnetic

Ferrite stainless steel

Common ferritic stainless steel grades such as 430 have a chromium content of approximately 16% to 18%.

-Good corrosion resistance

-Magnetic

-High thermal conductivity

Martensitic stainless steel

Common martensitic stainless steel grades include 410, etc. It contains about 11.5% – 13% chromium and about 0.15% carbon.

-High strength and hardness (after heat treatment)

-Relatively weak corrosion resistance

–Magnetic

Advantages in sheet metal fabrication

- Excellent corrosion resistance

- High strength and toughness

- Good processability

- Attractive and durable

- Good dimensional stability

- Recyclable

Stainless steel fabrication features

- 304

For 304 stainless steel sheets with a thickness of around 0.5 – 10 mm, nitrogen is commonly used as the auxiliary gas.

When cutting 304 stainless steel with a thickness greater than 10 mm, oxygen is sometimes selected as the auxiliary gas as well. - 316

For 316 stainless steel thin sheets (with a thickness generally ranging from 0.5 to 10 mm), nitrogen is the preferred auxiliary gas.

When cutting thicker 316 stainless steel (with a thickness greater than 10 mm), if it is necessary to improve the cutting efficiency, oxygen can also be considered for use as the auxiliary gas. - 430

For 430 stainless steel, whether it is thin plates or thick plates, nitrogen is usually used as the main auxiliary gas.

Bending process

Compared with common metal materials like ordinary low-carbon steel, stainless steel has higher strength and toughness.

When bending stainless steel sheets, more external force is needed for plastic deformation, and the pressure of the bending machine should be increased to the range of (X + 0.2X – 0.5X) tons.

Also, the surface roughness of the molds is usually required to be no higher than Ra0.8μm to avoid damaging the stainless steel sheets at the bends and ensure the appearance quality of the bent sheets.

Welding process

Common welding methods used in stainless steel sheet metal processing include TIG welding, MIG welding, resistance welding, and so on.

–TIG welding can produce high-quality welds with a smooth and flat appearance on the surface and good internal quality. It is suitable for welding thin stainless steel sheets (with a thickness generally ranging from 0.5 to 6 mm).

–MIG welding is appropriate for welding thicker stainless steel sheets (with a thickness generally ranging from 3 to 20 mm). It offers a relatively fast welding speed, but it demands higher requirements for the welding environment and operating techniques.

Stainless steel itself has good surface quality. Its surface is smooth, shiny, and has a metallic luster. It can achieve a certain decorative effect without additional surface treatment after processing. However, in some special cases, further surface treatment is still necessary.

Common surface treatment methods include polishing, brushing, electroplating, spray painting, etc. Polishing can make the surface of stainless steel even smoother and shinier, achieving a mirror-like effect.

Conclusion

As mentioned at the beginning, it is no accident that stainless steel is highly favored in sheet metal processing, especially in the manufacturing of electrical enclosure.

Its excellent material properties, diverse processing methods, and rich surface treatment means have jointly established its important position in this field.

Read more about our stainless steel product on yinlu-sheetmetal.com

and request for a quote today.

Share this article