Table of Contents

What is a control box

- Betty

The control box is one of the core components of the electrical system.

Figure No.1 Control box

Control box introduction

A control box is a type of equipment widely used in the fields of electrical, electronics, and automation. It is a box structure that centrally houses various control elements, protective devices, and related circuits.

Its main purpose is to effectively manage, control, and protect specific electrical systems, equipment, or technological processes, ensuring that they can operate stably, efficiently, and safely according to predetermined requirements.

Main function

- Centralized control

Centralize the control functions of multiple scattered electrical equipment or different parts of circuits in one control box. - Security protection

Provide protective devices such as circuit breakers and fuses, which can cut off the circuit in a timely manner to prevent electrical equipment from being damaged due to excessive current. - System monitoring and fault diagnosis

Through components such as sensors and monitors, continuously monitor the operating status of the electrical system as well as conduct fault diagnosis.

Composition of the control box

- Enclosure

There are two common materials for control box enclosures, namely metal and plastic, and the material selection should be made according to the usage environment. - Control element

It realizes circuit control, parameter adjustment, signal processing, logical control and other functions, ensuring the effective operation of electrical systems and equipment.

-Switch

-Contactors and relays - Protective device

The protective devices in the control box can deal with situations such as overload, short circuit, overvoltage, and undervoltage to protect electrical equipment and systems. Meanwhile, they ensure the safety of personnel and enable them to operate stably and safely.

-Circuit breaker

-Fuse wire - Circuit connection

The connection between the wires of external devices and the circuits inside the control box enables signal transmission.

-Terminal

-Wire and cable - Signal processing and display

Conduct human-machine interaction through the HMI (Human Machine Interface) to achieve visual operation.

-Controller and processor

-Display or indicator

Types of control box

Due to the wide variety of differences in actual application scenarios, control boxes are usually manufactured in various forms. Among them, the commonly favored forms mainly include the following.

Industrial control box

The main functions of industrial control boxes are to centrally control and manage various types of equipment in industrial production, ensuring the efficient, stable, and safe operation of industrial production.

Figure No.2 Industrial control box

Residential control box

The main function of the residential control box lies in centrally controlling and managing various electrical circuits and electrical equipment within the residence, ensuring the stable and reliable electricity usage of the family.

Commercial control box

Conduct centralized management and control over numerous electrical equipment and circuits in commercial venues to ensure the safety, stability, and high efficiency of electricity usage in commercial operations.

PLC control box

The main function of the PLC control box is to carry out automated control and monitoring on various types of equipment through the programmable logic controller.

Figure No.3 PLC control box

Wall mounted control box

It is mainly used to be installed on the wall to conduct centralized control and management on relatively fewer and lower-power equipment.

Figure No.4 Wall mounted control box

Floor standing control box

It usually has a larger volume and strong bearing capacity, and can control more and higher-power equipment.

Figure No.5 Floor standing control box

Flush mounted control box

It can be embedded in the installation surfaces such as walls and cabinets, which not only realizes the effective control of relevant equipment but also integrates with the surrounding environment, enhancing the aesthetics.

Yinlu's Customizable Control Box Solutions

Yinlu will help you design a fully functional, reliable, safe and good apperance control box.

The following is the complete design process, You can contact us if you need anything!

Define control needs

Firstly, it is necessary to clearly identify which equipment or systems the control box is used to control and specify the exact control functions that need to be achieved.

Consider electrical parameters

Determine the current and voltage specifications of the control box according to the voltage and current of different controlled equipment.

Select the appropriate control element

Select appropriate switching devices such as circuit breakers, contactors, and relays based on the control requirements and electrical parameters.

Plan control box layout

–Component layout

Arrange the placement positions of various electrical components inside the control box reasonably to facilitate the operation by users.

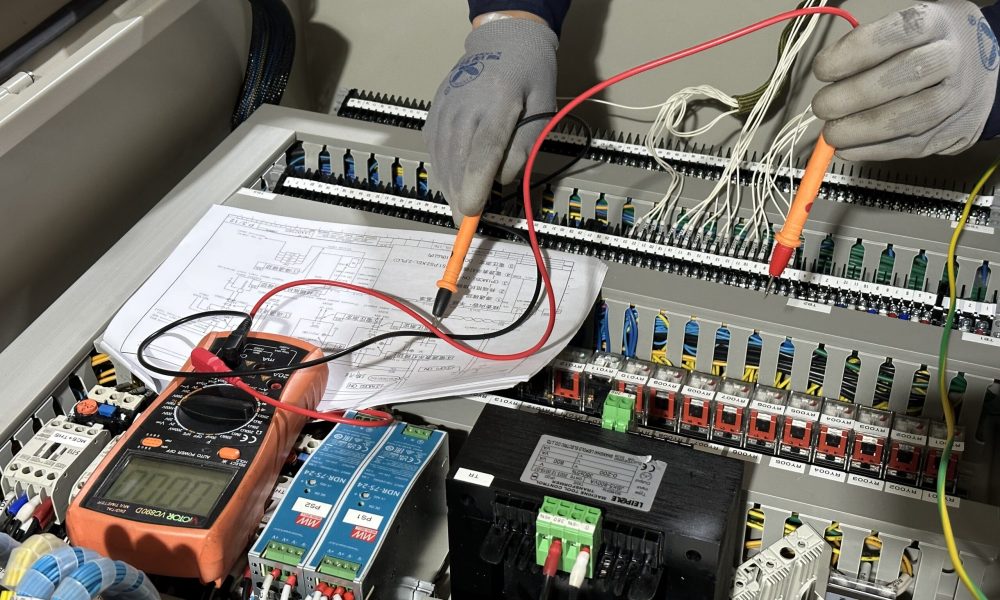

–Wiring design

Carefully design the wiring scheme inside the control box to ensure that the lines are clear and neat, avoiding the chaos of line crossings that may cause potential safety hazards.

Figure No.6 Control box wiring checking

Safety protection

–Electrical safety

Set up reliable grounding devices and install leakage protection devices, etc.

–Mechanical protection

Select the corresponding protection level according to the usage environment of the control box.

·IP Rating

·Name Rating

·UL Certification

Man-machine interface

Determine convenient and intuitive operation methods, such as operating through buttons, knobs, touch screens, etc.

Figure No.7 HMI control box

Heat dissipation design

Based on the heating situation of the electrical components inside the control box, select appropriate heat dissipation methods. Common heat dissipation methods include natural ventilation, forced ventilation, and heat dissipation by radiators.

Cost control

Finally, on the premise of meeting the control requirements, we will comprehensively consider and select electrical components with high cost performance. Meanwhile, we will reasonably arrange the production process to reduce labor costs and material costs so as to provide the most cost-effective solutions.

Conclusion

The control box brings standardization and guarantee to the operation and management of the entire electrical system. Therefore, choosing a reliable product and supplier is of crucial importance.

Yinlu has been specialized in control boxes for 30 years. We are quite confident that we can provide you with such products. We are committed to providing one-stop control box solutions. So please feel free to contact us soon.