Electrical Enclosure & Cabinet Manufacturer

- Electrical enclosure prototype design

- Quality assurance

- Custom IP rating

For the past 30 years, Yinlu has been focusing on creating electrical enclosures with diverse styles, specifications, structures, materials and protection levels.

With our rich experience and excellent techniques, we will provide customized electrical enclosures that perfectly match your needs.

We are definitely a professional electrical enclosure supplier worthy of your trust.

Electrical Enclosure Series Product

Electrical Enclosure Fabrication Capacity

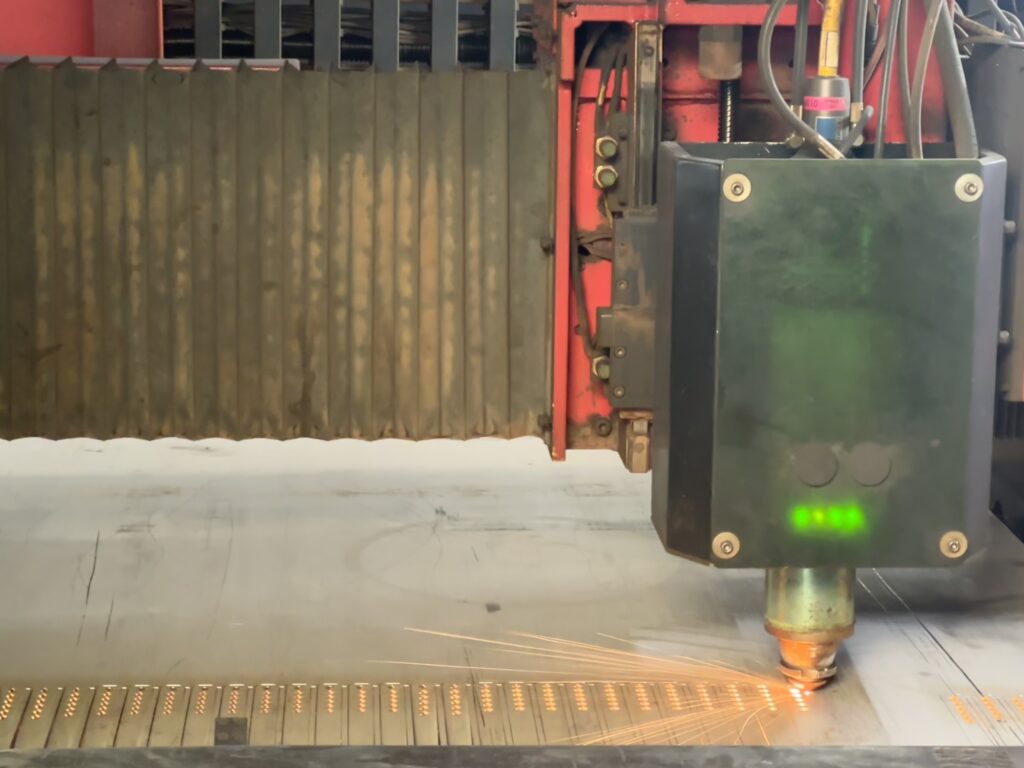

Laser Cutting For Electrical Enclosure

Bending For Electrical Enclosure

Welding For Electrical Enclosure

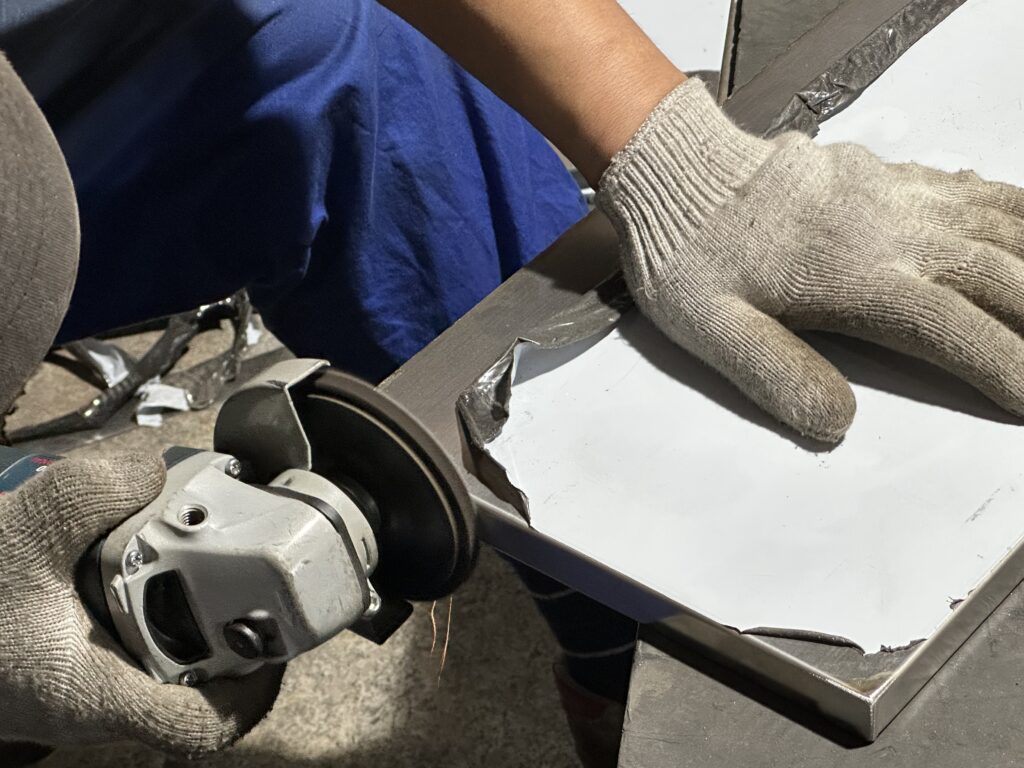

Polishing For Electrical Enclosure

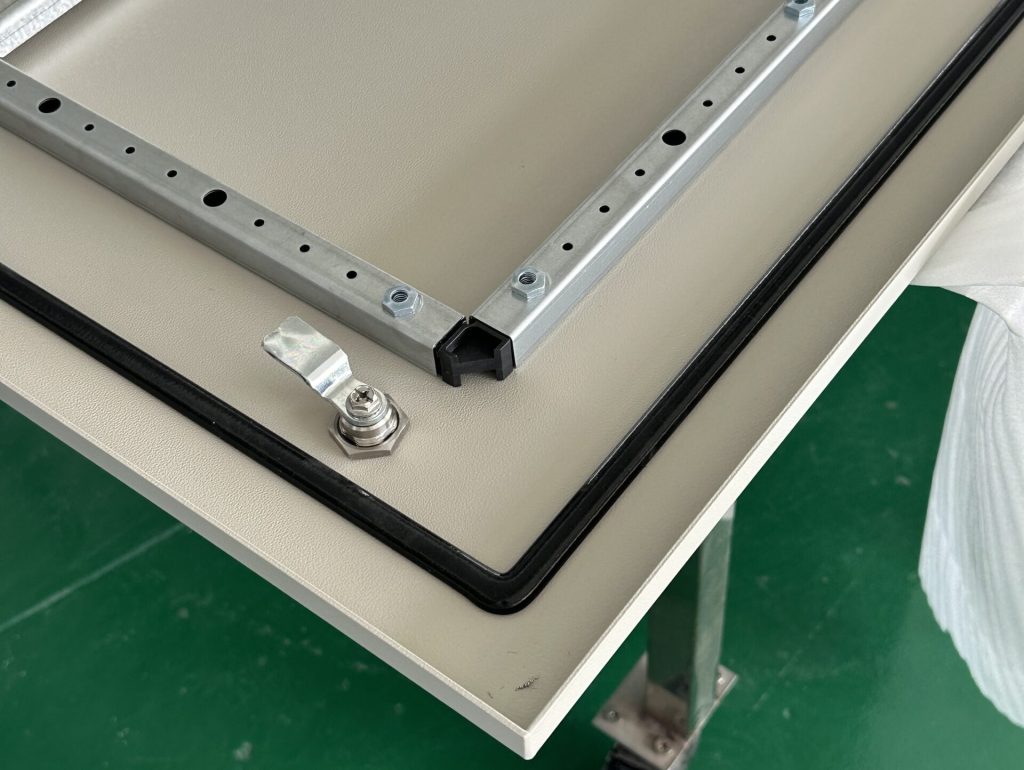

Foaming For Electrical Enclosure

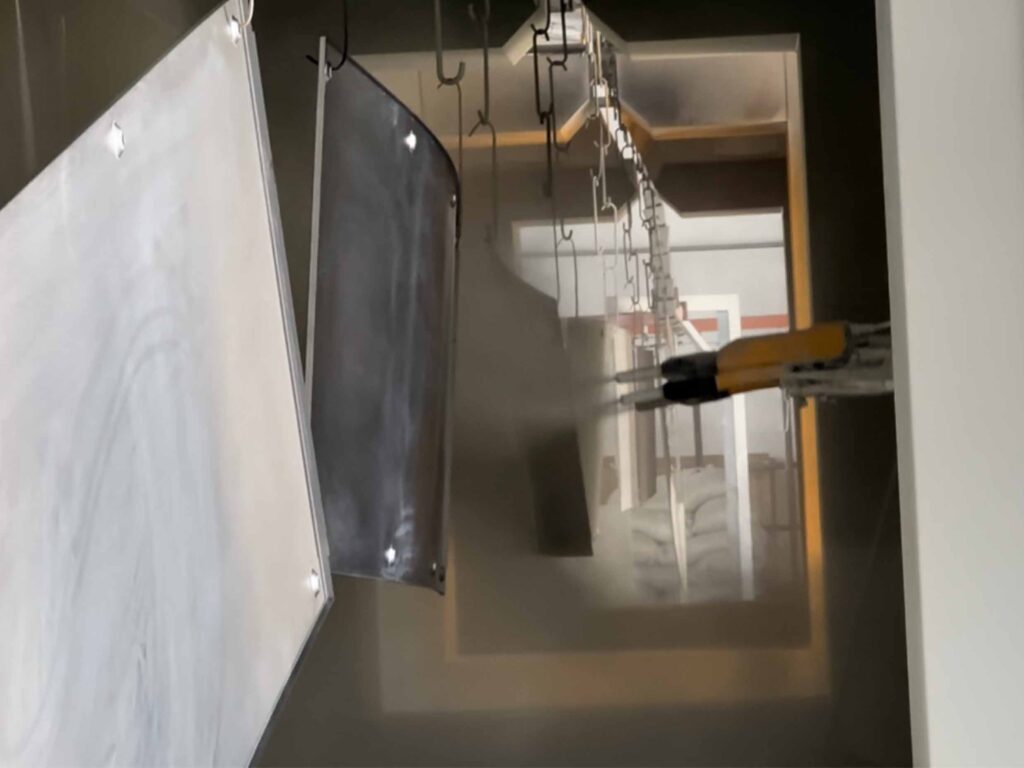

Powder Coating For Electrical Enclosure

Table of Contents

Professional Electrical Enclosure Manufacturer

- Betty

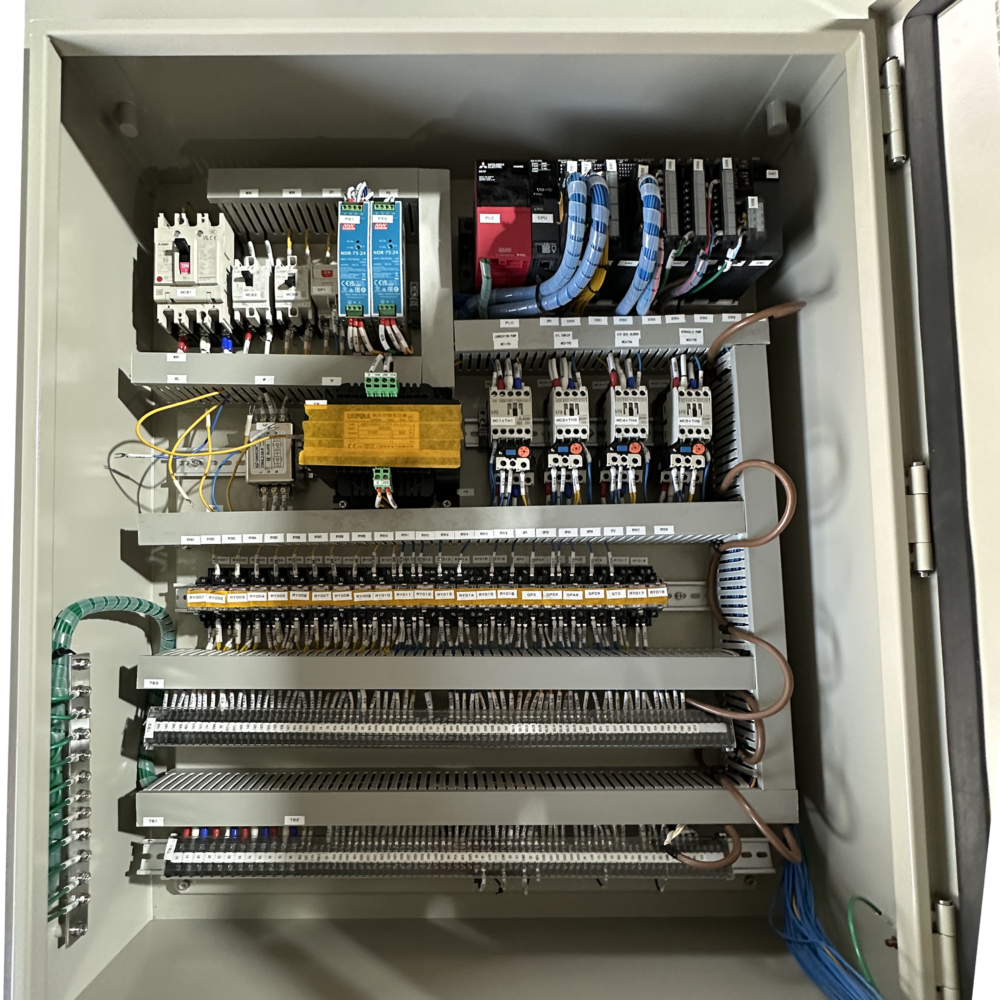

Figure No.1 Electrical Enclosure Display

What is electrical enclosure

Briefly speaking, an electrical enclosure is a closed physical structure with a certain amount of space inside, which can hold some electrical equipment and electrical components. It protects the internal equipment from being damaged by external environmental factors and also prevents people from accidentally touching the live parts.

In terms of materials, electrical enclosures have multiple options. And they have different protection levels, providing varying degrees of protection against water, dust, wind and rain, and electric shock.

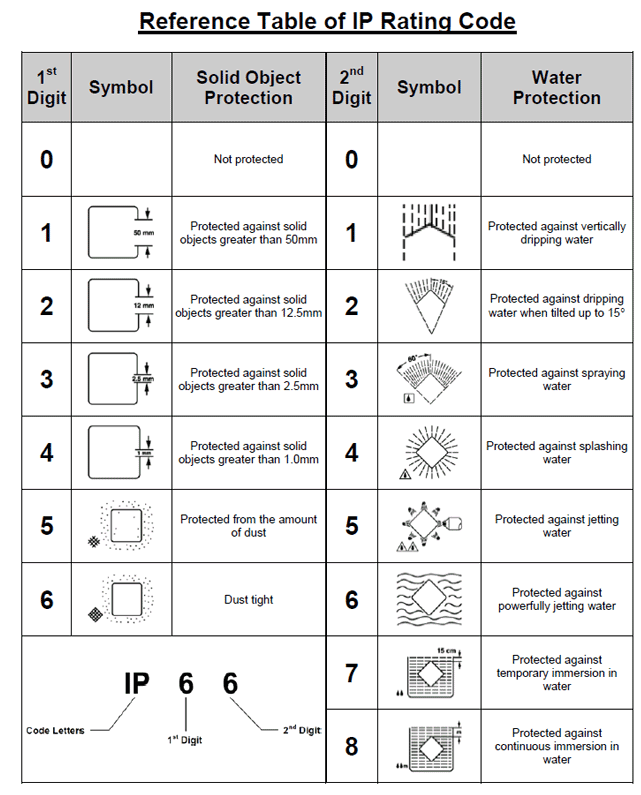

Electrical cabinet standard

It is an international standard formulated by the International Electrotechnical Commission (IEC).

It’s an electrical enclosure standard widely used around the world and applicable to all kinds of electrical equipment.

The IP protection rating mainly focuses on two aspects, namely dustproof and waterproof, and it details different levels of dustproof and waterproof.

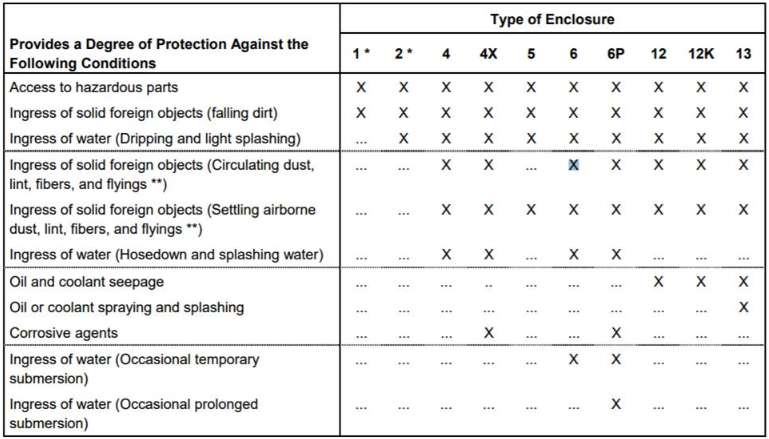

NEMA

This is a standard developed by the National Electrical Manufacturers Association (NEMA). This standard is mainly applied in the United States and North America.

Compared with the IP rating, in addition to having specific protection requirements for dustproof and waterproof, it also specifies multiple protection capabilities such as explosion-proof, corrosion resistance and oil resistance.

Main types of electrical enclosure

Electrical enclosures come in a rich variety, and there are different classification methods.

For example, they can be classified by materials, protection functions, installation methods, usage environments, manufacturing processes, application fields and so on.

No matter what type of electrical enclosure you need, Yinlu can deliver the products to you with guaranteed quality and quantity.

Distinguish by materials

- Stainless steel

- Cabon steel

- Galvanized steel

- Aluminum

- Plastic

- Composite material

Classify by protection function

- Dustproof

- Waterproof

- Anti-explosion

- Anti-electromagnetic interference

Based on instsall methods

- Flush mounted

- Wall mounted

- Floor standing

According usage environment

- Indoor

- Outdoor

- Industry

Classification by processing method

- Die cast

- Injection molded

- Sheet metal

- 3D printed

By application

- Electric power system

- Communication equipment

- Industrial automation equipment

- Automotive electronic equipment

Types of sheet metal enclosures Yinlu can produce

The manufacturing strength of Yinlu in the field of electrical enclosures is obvious to all. We can provide you with all types of electrical enclosures mentioned above with high quality and high cost performance to meet all your needs.

If you have any questions related to electrical enclosures, you can contact us. We will provide you with customer cases of electrical enclosures for different industries and purposes for your reference.

Figure No.2 Electrical Enclosure Production Process

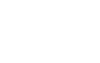

Figure No.3 Complete Power Distribution Equipment

Figure No.4 Electrical Enclosure Product Display Workshop

Figure No.5 Multiple Colors Electrical Enclosure

Figure No.6 Multiple Application Electrical Enclosure

Custom electrical enclosure services

We focus on providing comprehensive and high-quality customized services for electrical enclosures.

We are good at producing electrical enclosures that perfectly match in aspects such as size, shape, material and protection function according to the unique needs of customers.

What are the uses of custom electrical enclosures

It can meet the usage requirements of specific environments.

If used in some harsh environments, ordinary standard electrical enclosures will completely lose their functions.

Because standard products usually don’t have a high protection level. Generally speaking, they are mostly used in indoor environments.

However, non-standard customized electrical enclosures can usually flexibly customize the protection level according to the usage conditions of the products, enabling the products to reach an IP67 or even a higher protection level.

Optimize equipment performance.

For some medical equipment and high-precision electronic instruments, they are electrical equipment that is sensitive to electromagnetic interference.

It is necessary to use some materials with electromagnetic shielding functions for manufacturing.

Meet the needs of personalized aesthetics and brand image.

Customized electrical enclosures can completely become the carriers for brand promotion.

During the manufacturing process, processes such as powder coating and screen printing on the surface can achieve diverse appearance effects of the products to fulfill the purpose of brand promotion.

The best material to use for electrical enclosure

Generally speaking, metal materials are the most commonly used processing materials for electrical enclosures. For example, galvanized steel, carbon steel, stainless steel and so on.

We offer a variety of metal materials for the manufacturing of electrical enclosures. You can make choices regarding different materials, different thicknesses and different surface treatments according to your specific needs.

Figure No.7 Galvanized Steel

Figure No.8 Stainless Steel

If you need to learn about the content related to material selection and surface treatment, you can click to view it. You can also contact us and send us your needs. We will reply to you as soon as possible.

At Yinlu, our professional design team will develop the most comprehensive electrical enclosure solution for you.

We look forward to your consultation here.